An international research team has developed a closed-loop PV cooling system that can reportedly operate continuously 24 hours a day. The system is said to be particularly suitable for hot and dry areas and improves the lifespan of solar panels by up to 8.2%.

Scientists from Britain’s University of Nottingham and China’s Southwest Jiaotong University have developed a new closed-loop hydronic PV cooling system for hot and dry areas. “We believe that this proposed system will demonstrate good economic performance. We plan to conduct a detailed economic analysis of this system for specific application scenarios in the future,” said corresponding author Dr. Qiliang Wang. PV magazine.

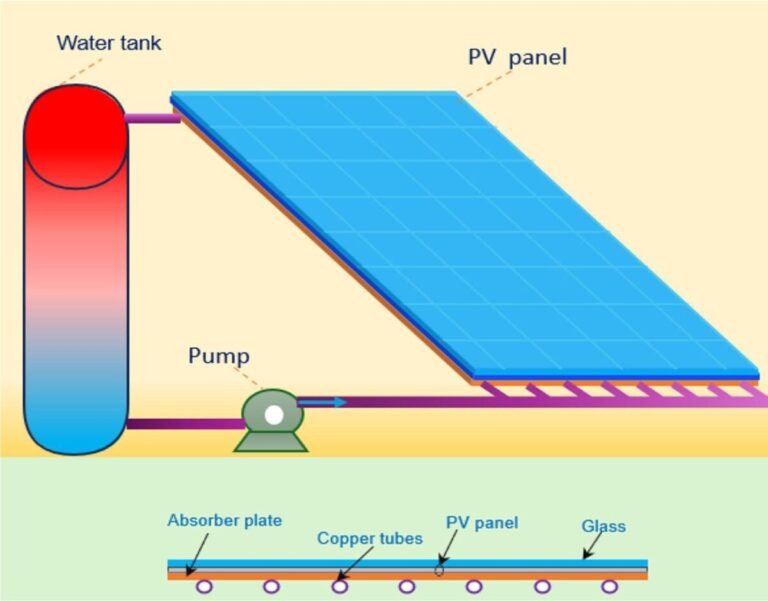

The closed system consists of a 15% efficient multi-layer PV module, a water tank with a capacity of 150 L, water pipes and a circulation pump. An absorber plate is placed on the back of the panel and copper water pipes are welded to the back of the absorber plate. The water tank forms a completely closed loop to which the pump and the PV module are connected via water pipes.

According to the researchers, the system can operate in a 24-hour continuous water circulation mode. First, the water circulates through the back surface of the PV panel during the day, effectively cooling it. At night, the continuous water circulation returns the accumulated heat to the PV panel, improving the temperature at night. This use of thermal energy reduces PV temperature fluctuations between day and night and is said to improve the lifespan of the PV panel.

The proposed setup was modeled via Comsol software, based on conditions in the Iraqi city of Basra. Attached to the panel were two copper manifolds and eight water pipes through which water flowed in to cool and heat the PV panel.

“The proposed design deliberately excludes an insulation layer for the water tank and water pipes on the back of the PV panel,” the academics pointed out. “By omitting the insulation layer, the system ensures that thermal energy is released to the environment, preventing the water from reaching too high temperatures and having a negative effect on PV efficiency. In addition, the absence of insulation in the water tank and water pipes allows for better heat dissipation during nighttime drainage, ensuring that the water coolant is sufficiently cooled.”

The proposed system was then tested against a reference PV system without cooling and the test showed that the service life of the cooled PV system can increase from 18 years to 24 years because the operating temperature was on average 10 C lower. Furthermore, it generated 6.7% more output power than the benchmark system in December and 2.5% more in June.

After these tests, the proposed system was tested with different configurations. Factors checked included the effect of the size, shape and level of insulation of the tank, as well as the different number of pipes cooling the system and the speed of water flow within them.

“It has been observed that the performance gains start to level off once the tank volume exceeds 150 liters for a PV panel of 0.988 m2. The proposed system, with 150 L and 250 L, can generate 1.28% and 1.36% more power respectively compared to the conventional PV module,” the scientists said. “Different tank shapes appeared to have minimal impact.”

Furthermore, they found that changing the number of tubes from 5 to 12 improved power by 1.17% and 1.36%, respectively, compared to the reference PV system. Furthermore, they found that higher mass flow rates resulted in lower PV panel temperatures and improved electrical energy efficiency.

The system was described in the article “A closed-loop hydronic photovoltaic cooling system designed for hot and dry regions: performance evaluation and degradation rate/lifespan analysis,” published in Applied energy.

“Overall, this proposed closed-loop PV cooling system provides a sustainable and cost-effective solution for improving PV panel performance,” the researchers concluded.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.