A German research team has developed a new technique to recover and reuse methylammonium lead iodide (MAPbI3) from perovskite solar cells via solvent extraction. Such a recycling method can reportedly save up to 61% of costs in laboratory and industrial production.

A German research team from the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy, the Jülich Institute for Energy, has reported success in restoring each layer of a flat surface. methylammonium lead iodide (MAPbI3) perovskite solar cell using a layer-by-layer solvent extraction approach, followed by purification to restore quality.

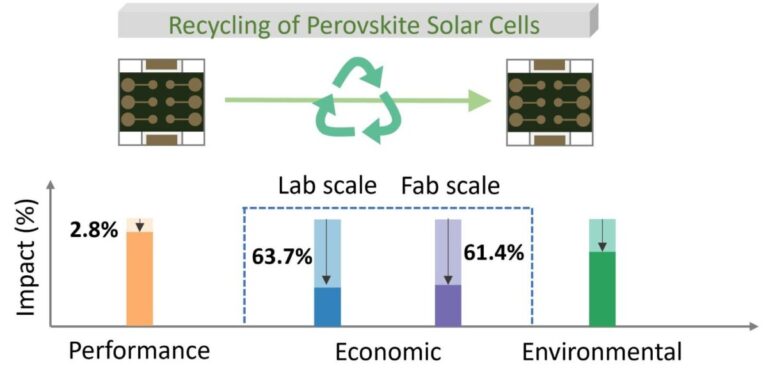

“This method potentially enables up to 99.97% recycled mass, saving raw materials and reducing waste,” the scientists said. “Techno-economic projections suggest that the proposed recycling procedure has the potential to deliver significant cost savings. In the laboratory, recycling could reduce material costs by as much as 63.7%, in industrial production by as much as 61.4%.”

“I was surprised that it was possible to recover such a high percentage of the original material, and that there is such a clear financial benefit to recycling, even on a laboratory scale,” said the study’s corresponding author Ian Marius Peters. pv magazine.

The researchers explained that halide perovskite solar cell materials can be recovered and processed to a quality that allows them to be used to make a new solar cell without significant loss of material quality and device efficiency. “Layers in solution-processed solar cells can be separated relatively easily by selective dissolution,” they pointed out.

The project sounds simple, but it wasn’t. Recycling the spiro-OMeTAD material used in the hold transport layer (hTL) was not easy due to the presence of residues and multiple additives, said Zhenni Wu, the study’s principal investigator. “Ultimately, we found that reusing spiro-OMeTAD while maintaining cell efficiency does not require the complete removal of impurities,” Wu said. pv magazine.

“We started with a laboratory process. The limitation was that we had to start virtually from scratch. We are still working on our setup. We then want to increase efficiency and show that you can also do this for a module,” says Peters.

To assess the quality of the recycled material, the team fabricated a variety of solar cells, some with multiple layers of recycled material, and some made entirely from recycled materials. “Each combination delivered efficiencies comparable to cells built solely with fresh materials, demonstrating the effectiveness of the developed recycling process,” the team said.

Two types of devices were assembled: one was a typical small-area functional cell fabricated with spin coating; another was a larger pseudo-module, manufactured with squeegees or drop-casting. The stack was as follows: indium tin oxide (ITO), a tin (IV) oxide (SnO2) layer, a MAPbI3 perovskite absorber, a spiro-OMeTAD hole transport layer and a gold (Au) contact.

The researchers noted that the stack was chosen for several reasons. One of these is that it allows selective removal of materials.

In a discussion about the value and weight of the material, the team highlighted that ITO glass has the “highest recycling priority” as it accounts for more than half of the value and makes up the majority of the module’s mass, at 99 .9%. . “Being able to reuse the substrate will impact both the economic viability and sustainability balance of the cell,” the report said, adding that the switch to FTO is worth considering.

Popular content

It also highlighted that the expensive spiro-OMeTAD requires a more efficient and scalable preparation method. Until replacements are found, recycling the material is ‘critical’. Another important aspect is the use of lead. The team said its presence in metal halide perovskite solar cells could necessitate the establishment of recovery processes as a prerequisite for commercialization.

As evidenced by the study’s findings, the adoption of recycling and environmentally friendly technology has implications for design and manufacturing. For example, the solvents used in the manufacture of perovskite solar cells.

Wu explained that most solvents currently used are dangerous. “Future research should focus on finding greener alternatives to reduce the carbon footprint. Likewise, environmentally friendly solvents should be prioritized in recycling processes,” said Wu.

“The conclusion is that you have to recycle components of perovskite solar cells, especially substrates. This applies not only to industry, but also to laboratories,” says Peters.

The details of the investigation appear in the newspaper “Closing the loop: recycling MAPbI3 perovskite solar cells,” published in Energy and environmental sciences.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.