A group of researchers in Thailand outlined a new methodology to identify the optimal temperature in two-stage cascade heat pumps using non-azeotropic refrigerants. Through their analysis, the scientists discovered that the coefficient of performance for simultaneous heating and cooling is affected by the bottleneck temperature at the cascade heat exchanger, with lower temperature levels responsible for a higher COP.

Researchers from Chiang Mai University in Thailand have proposed a new approach to find the optimal temperature to increase the coefficient of performance (COP) of two-stage cascade heat pumps using non-azeotropic refrigerants.

Despite their limited success in industry, non-azeotropic refrigerant mixtures are considered promising in heat pump applications, offering improved efficiency both in terms of coefficient of performance and compressor power.

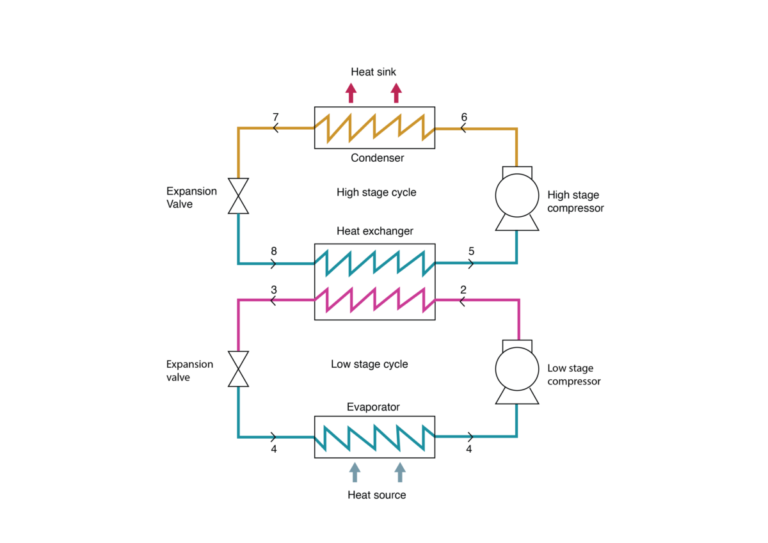

Two-stage cascade heat pump systems work as standard high temperature side (HS) cycles and low temperature side (LS) cycles that are connected via a heat exchanger. Each cycle consists of a condenser, an expansion valve, an evaporator and a compressor, with the total system including a heat exchanger and a heat sink and with all components in stable flow conditions.

During the LS cycle, the refrigerant is heated and vaporized in the evaporator and then exits as saturated vapor. This pressure is increased by the LS compressor under an isentropic process and the vapor is converted into a saturated liquid, which undergoes irreversible adiabatic expansion at the expansion valve and then re-evaporates by heat absorption at the low temperature evaporator.

During the HS cycle, the working fluid arrives at the heat exchanger as a saturated vapor and then moves to the HS compressor under an isentropic process. After condensation in the condenser, the working fluid turns into a saturated liquid, which is then reduced in temperature and pressure to re-enter the HS evaporator.

The academics explained that identifying the center temperature of these heat pump systems, as well as the condensation and evaporation temperatures of their HS and LS, has always been a difficult task. “In the case of non-azeotropic refrigerants, there is so far no general approach that can be used to indicate the optimum for a two-stage cascade heat pump to achieve the highest COP.,” they stated.

“For specified values of HS condensation and LS evaporation temperatures, an increase in the intermediate temperature leads to a corresponding decrease in HS compression work and an increase in LS compression work. Conversely, a reduction in the intermediate temperature results in the opposite effect. Then the total COP for simultaneous heating and cooling varies depending on the intermediate temperature,” they add.

Through their analysis, the scientists discovered that the COP for simultaneous heating and cooling is affected by the bottleneck temperature at the cascade heat exchanger, with lower temperature levels responsible for a higher COP. They also found that the intermediate temperature increases with both HS condensation temperature and LS evaporation temperature. “Most of the optimal temperatures were found to be lower than the average value of the HS condensation temperature and LS evaporation temperature,” they also explained.

They also concluded that the optimal temperature can be identified by considering the correlation of the correction factor combined with the average temperature between HS condensation and LS evaporation temperatures as a reference. “The results from the newly developed model for optimal intermediate temperatures and maximums COPs showed very good agreement with those calculated using the enthalpy method, with deviations within ±7% and ±3%, respectively,” they pointed out.

The proposed approach was described in the study “Optimal center temperature of two-stage cascade heat pump with non-azeotropic refrigerants for simultaneous heating and cooling”, published in Results in technology. Looking ahead, the group said it plans to test the method in multi-stage heat pumps designed for very high-temperature heating and low-temperature cooling.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.