Scientists in Spain have investigated the total or partial interruptions of ribbons that connect solar cells in modules and have proposed a classification based on their type and location.

A research group led by the Spain Center for Energy, Environmental and Technological Research (CIEMAT) has investigated various aspects of ribbon interruptions in PV modules and has proposed a classification based on their type and location.

The work was done on modules where each cell is connected to two ribbons. While one Previous work Had aimed at cases of twin interruptions, where both parties are affected, the most recent work emphasizes the cases of some interruptions.

“It has been shown that photovoltaic panels of the second -hand can function satisfactorily after they have been repaired. One of the most frequent breakdown of photovoltaic modules, which forms about 10% of the causes of failure, is caused by interruptions of the conductive strip between two cells, “the team said. “An important aspect for repairing module interruptions must be the development of simple and cheap techniques, so that there is an economic advantage of the repair compared to direct recycling.”

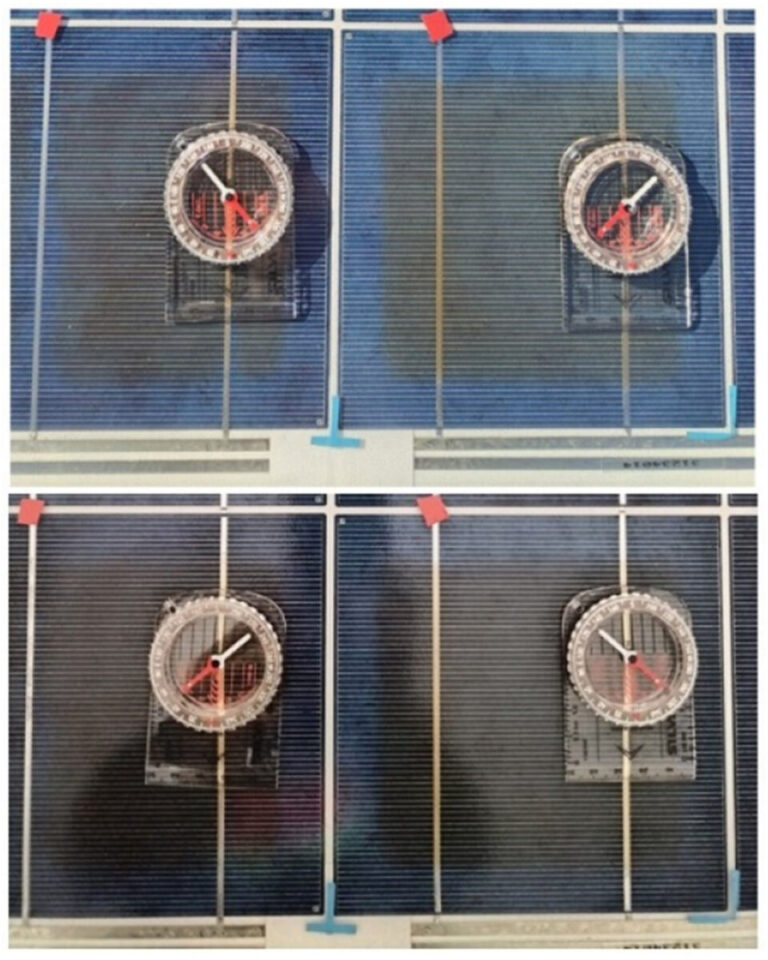

The scientists have started comparing different types of methods for detecting some interruptions. The first method uses the imaging of electroluminescence (EL) and makes an image of the light emittering module in the dark. The second method uses an anisotropic magneto resistance (AMR) magnetic sensor that moves along the ribbons, to look for sudden drops in the magnetic field. The third method uses a simple compass. While the current of the PV generates a magnetic field that makes the needle, an area where it goes back to the natural direction interruption.

The compression also included a detection method of twin interruptions, which was developed in an earlier work by the group. It uses a tone detector sensor that broadcasts an audible signal as long as there is an electrical continuity in the ribbons. All four methods were tested for four defective PV modules with a maximum power of 215 W.

Image: CIEMAT, Renewable Energy, CC by 4.0

“The proposed method that uses a magnetic compass shows results that coincide fully with those of EL images and results obtained with two types of electronic power locators,” the academics noted. “The use of an AMR sensor has been demonstrated for the location of a few interruptions, which can be used as a portable instrument in real installations under normal operating conditions. In addition to finding a few interruptions, this device makes numerical characterization of ribbon streams possible, as well as the flows on the surface of the cells. “

The next step of the study was to classify the ribbon break on a more accurate level than just twins or single. Two more classes were identified, namely delayed a few interruption and delayed twin interruption. The first refers to a new single interruption that appears after repairing an earlier single interruption; While the latter occurs when a second interruption appears in the same cell where a delay some interruption already took place.

The researchers discovered that repairing double interruptions is repairing large values of lost current, whereby some interruptions repair up to 6% more than the situation reaches after repairing the twin interruptions. “For the analyzed modules, repairing all interruptions increased the generated power to 320%,” the group stated “in the analyzed modules, the repair of all, (twin and a few) interruptions an improvement of a maximum of 25% in module vulffactor.”

The results of testing were presented in “Progress in the location and repairing ribbon interruptions in photovoltaic modules“Published in Renewable energy. Researchers from the IMEC of Belgium and the BP Solar office of the country also participated in the study.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content