How efficiently solar cells can be made with non-toxic processes

Efforts to produce environmentally friendly and efficient solar cells have taken a significant step forward thanks to a new design principle developed by researchers at Linkoping University in Sweden. This approach, detailed in a study published in Nature Energy, investigates how the shapes and interactions of molecules influence the performance of organic solar cells.

“With electrification and the development of AI, we are likely to see a significant increase in the world’s energy needs. That electricity must come from environmentally sustainable sources if we are to simultaneously slow climate change,” says Professor Feng Gao. of optoelectronics at Linköping University.

Promoting organic solar cells

Organic solar cells, which use electrically conductive plastics, are emerging as a promising alternative to traditional silicon-based solar cells. These solar cells are not only light and flexible, but also relatively cheap to manufacture. Their unique properties make them suitable for a variety of applications, from portable electronics to integration into windows or interior surfaces.

Currently, organic solar cells reach an efficiency level of almost 20%, comparable to traditional solar technologies. This advancement comes from extensive research into the molecular interactions of the materials and their influence on performance, known as morphology. However, the manufacturing process is still highly dependent on toxic solvents, which poses challenges in terms of scalability and environmental safety.

Groundbreaking non-toxic production

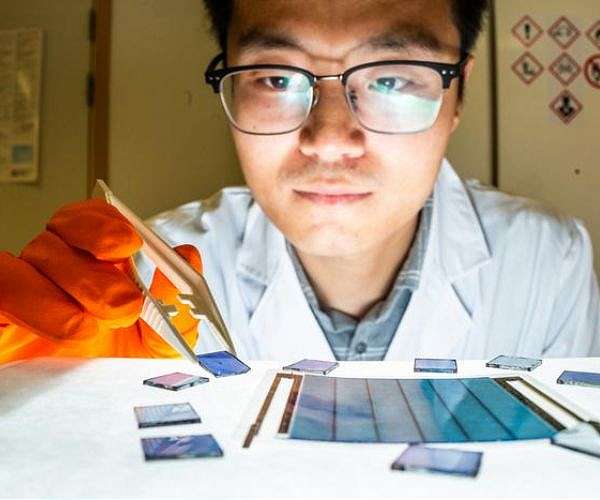

To address these concerns, Feng Gao’s research team, in collaboration with experts from China and the United States, has developed a method to produce organic solar cells using environmentally friendly solvents. These advances pave the way for safer, large-scale production techniques, such as printing.

“To achieve mass production of organic solar cells, for example with printed technologies, on a large scale, we need to find methods that do not use toxins. Otherwise it is not good for the environment and for those who work in the factories.” Feng Gao explained.

Using advanced synchrotron X-ray and neutron techniques, the researchers mapped the molecular interactions between the materials and solvents used in production. This allowed them to establish a design principle compatible with various harmless solvents, and they are optimistic that even water could serve as a solvent in the future.

Towards sustainable solar energy technologies

The study highlighted the complexity of organic solar cell manufacturing, especially the relationship between morphology and performance. The team investigated the ultrafast electron movements and interactions at the nanoscale that underlie charge transport in the material. Understanding these processes marks a crucial step toward environmentally sustainable solar energy technologies.

“Thanks to a toxic-free production method, we now have a much greater chance of commercializing the technology on a larger scale,” Feng Gao concluded.

Research report:Equally high efficiency of organic solar cells processed from different solvents reveals key factors for morphology control