In a new weekly update for pv magazineOPIS, a Dow Jones company, provides a brief overview of the major price trends in the global PV industry.

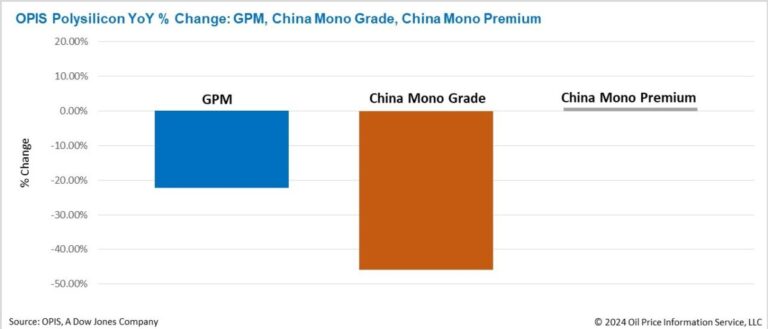

The Global Polysilicon Marker (GPM), the OPIS benchmark for polysilicon outside China, was valued this week at $20,360/kg, or $0.046/W, flat from the last assessed price on December 17, thanks to unchanged market fundamentals.

Some GPM manufacturers have reportedly resorted to production cuts, with operating rates falling to around 30% in certain periods. However, demand remained weak and suppliers are reluctant to reduce prices further, stifling market transactions and hampering all revitalization efforts.

Despite these challenges, optimism remains about the prospects of the GPM market given its close ties to trade policy. On the one hand, China’s cheap products continue to weigh on GPM prices, as modules made with traceability-compliant Chinese polysilicon are not completely excluded from the US market. On the other hand, industry insiders view the possible implementation of clearer and stricter US restrictions on Chinese solar products as a “critical route” for revitalizing the global polysilicon market and express confidence in the likelihood that such measures will be implemented entered.

The China Mono Grade, OPIS’ assessment of mono-grade polysilicon prices in the country, remained stable this week at 33 yuan/kg, equivalent to CNY 0.074 ($0.010)/W. Meanwhile, China Mono Premium, OPIS’s price assessment for mono-grade polysilicon intended for n-type ingot production, rose slightly by 0.96% to reach CNY 39.375/kg, or CNY 0.089/W, compared to last assessed price. on December 17.

In the last week of 2024, China’s two leading polysilicon manufacturers, Tongwei and Daqo, released official statements announcing production cuts. Both companies cited compliance with a previously signed “self-regulatory agreement,” aimed at controlling production capacity and curbing harmful competition, as the rationale behind these reductions. While the specific extent of these production cuts was not disclosed, OPIS market surveys revealed that one of the manufacturers has completely halted operations at its plants in Yunnan and Sichuan. Currently, only the Baotou production base in Inner Mongolia is still operational, with a monthly production of approximately 20,000 tons. Considering the company’s annual production capacity of approximately 900,000 tons, this equates to an operating rate of approximately 26%.

The industry broadly expects the problem of overcapacity in polysilicon production to persist until 2025. China’s polysilicon inventory of 400,000 MT by the end of 2024 could sustain wafer production for four months without new production. Furthermore, it was highlighted that administrative measures, such as ‘self-regulation’ to maintain low operating rates, could become standard practice by 2025.

The official launch of polysilicon futures trading in the last week of 2024 is believed to have contributed to this week’s n-type polysilicon price increase. Experts see this initiative as a potential solution to reduce inventory overhang, stabilize prices by 2025 and address overcapacity. However, no wafer producers have yet purchased polysilicon through the futures market, with most participants being traders. This suggests that futures trading is still in its early stages. At this point, insiders estimate that the impact may be more financial than physical, with actual physical deliveries expected to account for only 30% to 50% of total trading volume.

OPIS, a Dow Jones company, provides energy prices, news, data and analysis on gasoline, diesel, jet fuel, LPG/NGL, coal, metals and chemicals, as well as renewable fuels and environmentally friendly feedstocks. It acquired assets with pricing data from Singapore Solar Exchange in 2022 and now publishes the OPIS APAC Solar Weekly Report.

The views and opinions expressed in this article are those of the author and do not necessarily reflect those of the author pv magazine.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content