EnPV GmbH, a subsidiary of German energy supplier EnBW Energie Baden-Württemberg AG, has unveiled a solar cell based on n-type tunnel oxide passivated contact (TOPcon) technology and a new type of back-contact architecture, which is described as self-aligned back contact (SABC) technology.

“Common interdigitated back-contact (IBC) solar cells require an interdigitated pattern that is not homogeneous in nature and must protect parts of the back surface of the wafer during some steps in production,” EnPV CEO Massimo Centazzo told us. pv magazine. “Our SABC cell production avoids masking to structure the back surface and, while we use laser structuring instead, it manages phase isolation without any additional specific process steps.”

Centazzo explained that phase isolation consists of “reliably” isolating the p and n phases from each other via a byproduct of other process steps, which explains why it is “self-aligned.”

“The use of both techniques, laser processes for structuring and self-aligned phase isolation, dramatically simplifies the manufacturing process compared to any other back-contact cell process,” said the CEO. “While SABC cells still enable higher cell efficiency, they are produced at a lower cost than TOPCon and heterojunction (HJT) cells.”

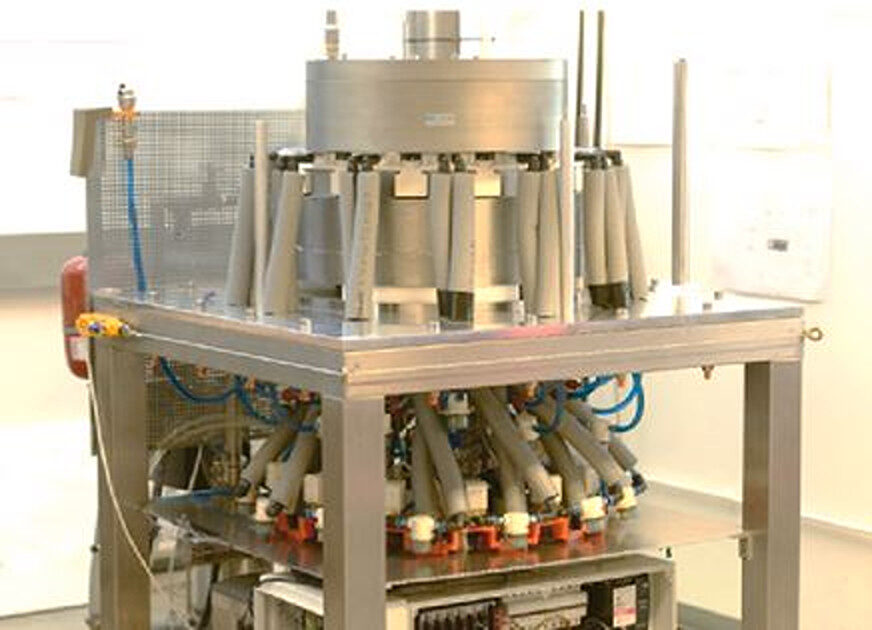

The manufacturer claims that the new back contact technology can be easily used in existing TOPCon cell production lines, with the upgrade requiring the addition of a wet chemical process, a laser structuring process step, the deposition of an etch barrier and the physical vapor deposition. -based deposition of doped amorphous silicon for the n-contact.

“Our approach does not require a special trench to isolate the poly-Si layers of opposite polarity,” Centazzo continued. “Instead, the undercut of the trench wall separates the two polarities, with the first p-type poly-Si layer lying on top of the trench surface, while the second n-type poly-Si is on the bottom of the trench.”

Image: EnPV GmbH

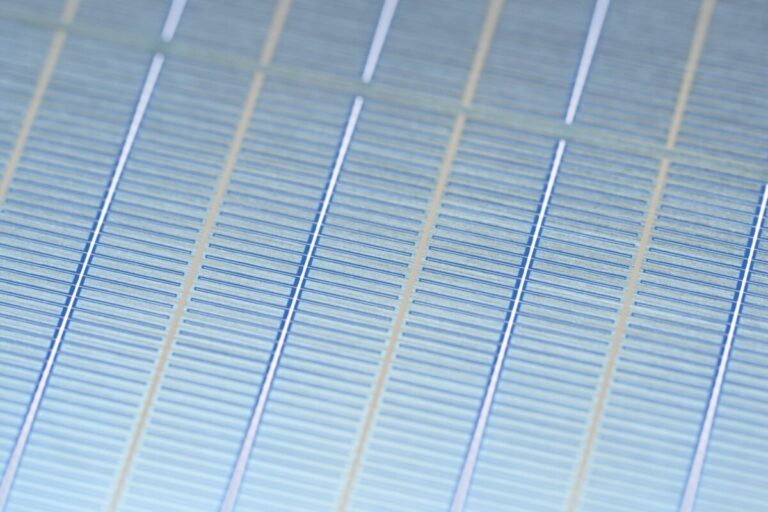

Under the undercut, which is performed via wet chemical etching of the trench, no poly-Si is deposited during the physical vapor deposition (PVD) process. The n-type poly-Si also covers the p-type poly-Si emitter and forms a low-resistance tunnel contact, as both poly-Si layers are highly doped with doping concentrations greater than 1,020 cm2.3. The n-type poly-Si layer covers the entire surface and allows the use of the same metallization scheme for both polarities, according to the manufacturer.

Centazzo also explained that the SABC target process begins with texturing and boron diffusion on both the front and back sides. “A single-sided etching of borosilicate glass (BSG), followed by alkaline etching of the bore transmitter on the back, prepares this surface for the poly-Si deposition,” he pointed out. “Instead of the boron diffusion forming the front floating emitter (FFE), a phosphorus diffusion forming a front surface field (FSF) or a non-diffuse surface could also be used for the SABC process stream.”

In alkaline wet chemical etching, the poly-Si on the front is removed up to the BSG layer and on the back the p-type poly-Si is etched in the exposed areas. The back etch not only removes the poly-Si layer, but also etch the silicon base vertically and laterally, creating an undercut of the surface. After removing the etch barrier and removing BSG and growing a second interfacial oxide, the subsequently PVD deposited n-type poly-Si will not cover the entire back surface.

“With the highly directional deposition technique, the doped silicon is deposited mainly on vertically exposed surfaces, which are not obscured by the undercut,” Centazzo points out. “Hence, at the bottom of the trench, n-type poly-Si forms a passivating contact, but there will also be an n-type poly-Si on top of the p-type poly-Si that forms a tunnel connection with the emitter. The shaded part of the slot wall isolates both passivating contacts, without the need for additional processing steps such as structuring, local etching or masking.”

The production process is then completed with high temperature annealing, crystallizing the poly-Si layers and activating the dopants, standard passivation with aluminum oxide (AlOX) and silicon nitride (SiNX), and metallization by screen printing. “Since the n-type poly-Si covers the surfaces of both passivating contacts, the same screen printing paste can be applied for both polarities in a single printing step,” Centazzo points out.

He believes that SABC TOPCon cells can be cheaper than conventional TOPCon cells.

“We expect an efficiency gain in the migration from TOPCon to SABC of more than 0.5% absolute at the cell level, and a further 0.7% at the module level due to lower cell-to-module losses from back-contact modules compared to normal modules ”, he added. . “The conversion cost from cell to system is €0.75 ($0.83)/W, while in an SABC-based system, due to increased module efficiency, it drops to €0.71/W, with cell production costs decrease from €0,100/W to €0.85/W. In total, a system based on SABC modules would cost €0.80/W, which is approximately 6% cheaper than a system with TOPCon cells.”

The new cell concept has a Technology Readiness Level (TRL) of 6. The TRL measures the maturity of technological components for a system and is based on a scale of one to nine, with nine representing mature technologies for full commercial deployment. According to the company, it could only move towards TRL class 8 if it is implemented on a pilot production line in a mass production environment.

EnBW is currently committed to financing the development of SABC cells, but the industrialization strategy is still under discussion. “Since EnBW’s territory for entrepreneurial activities is traditionally Germany and Europe, where PV production is declining, the search for suitable partners for the industrialization of SABC had to be extended beyond Europe,” said Centazzo, noting that EnPV is currently exploring the possibilities for launching of SABC in cell factories in the world’s hotspots for PV production, namely the US, India and China.

“We anticipate that we will be able to start a pilot line later in 2025,” he concluded. “No decisions have yet been made with which partner.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content