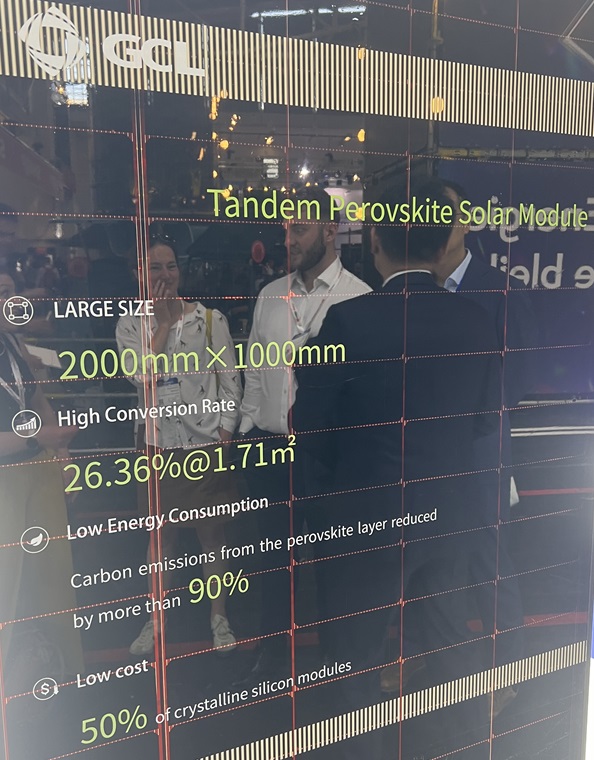

At Intersolar Europe, the Chinese manufacturer also said that the perovskite-silicon tandem module would cost 50% of a crystalline silicon module that costs $0.15 per W, which works out to $0.075 per W.

Chinese solar panel manufacturer CGL Technology presented its latest perovskite solar panel technology at the Intersolar trade show in Munich, Germany this week.

“This module meets IEC testing standards which indicate that the quality of the module will degrade in a pattern similar to standard silicon solar panels,” company spokesman Martin Wang said. pv magazineThe company notes that the company expects this perovskite product to be deployed as part of a perovskite-silicon tandem solar panel, which will begin mass production in late 2025.

Wang also revealed that GCL perovskite modules were used in the 1 MW perovskite solar power project deployed by China Three Gorges in late 2023.

The company said the deployment of its pure perovskite module at the China Three Gorges solar project represented the state-of-field testing phase of the product. The company hopes to implement multiple 1 MW projects in different regions with different environmental characteristics before the end of the year, to test the viability of the perovskite module.

On the stand, GCL showed two perovskite solar panels: one a pure perovskite module and the other a perovskite-silicon tandem solar module. The pure perovskite module has an efficiency of just over 19%, while the efficiency of the tandem module is just over 26%.

Wang explained that the perovskite solar panel had passed TUV Rijnland IEC 61215 and IEC 61739 certification tests, which would indicate that the solar panels would degrade in the same way as a standard silicon solar panel. Wang suggested that GCL was slow to come to market with that statement because the tests are designed to break down silicon products, not perovskite products.

GCL delivered pv magazine with the IEC certification document. Further documentation has been requested to better interpret the degradation results.

The modules came from a 100 MW test line that has been in use since 2021. The majority of the modules from this test line, which totaled 10 to 15 MW in 2023, have been recycled as the modules evolved into units they deemed valuable. of commitment.

Wang said GCL believes the degradation of their perovskite-silicon tandem module will be better than that of standard silicon modules. From the end of next year, GCL will start deploying their perovskite-silicon tandem solar panel.

An important detail of the product that differs from many others on the market is that the tandem aspect of the product is at the module level – and not at the cell level. What this means for the manufacturer is that “95% of the hard work” will already have been done in creating the perovskite module.

Wang also explained that combining two solar panels was a much simpler process than making a tandem solar cell, and that the units of the handmade perovskite-silicon tandem modules work 95% of the time, once the production line is in place. this value will reach almost 100%.

Wang said that based on cost per watt – not the expected market price – the company expected the perovskite-silicon tandem module to cost 50% of a crystalline silicon module that costs $0.15 per W, which works out to $0.075 per W He said that the 50% value used in marketing the perovskite silicon module was done when polysilicon was more expensive, and thus modules were more expensive.

At the request of pv magazine on future efficiency gains, Wang said GCL is – in this case – a perovskite company first. “We need to unleash the full potential of perovskites, and we need to adapt silicon to the perovskite – rather than the other way around,” he said.

They expect the tandem module to achieve 27% efficiency next year – with more than 30% “guaranteed”. Currently in the tandem structure it is the perovskite module that contributes most of the efficiency, as it generates an efficiency of 19%, while the silicon has only an efficiency of 7%.

The current basic silicon module used is a TOPCon unit. However, GCL believes that heterojunction will be the best solution in the long term due to the higher voltage of the product.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.