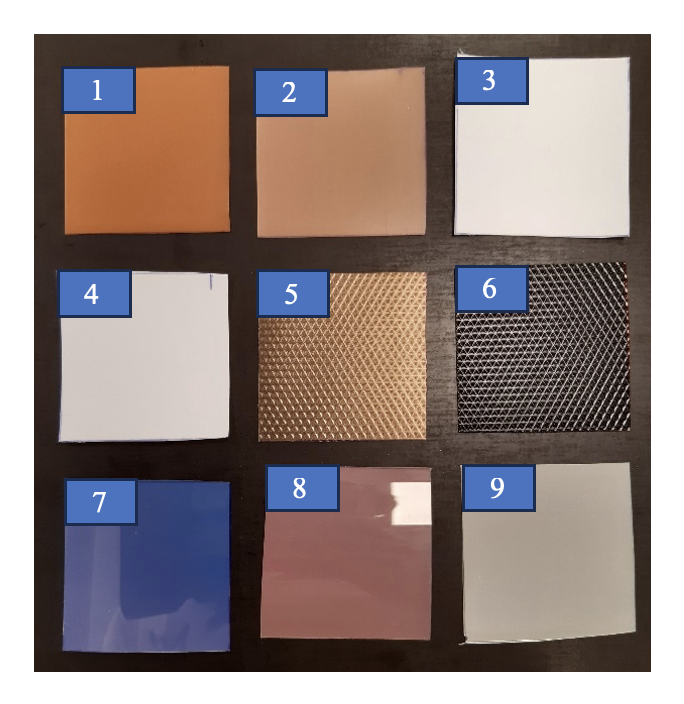

France-based Solarcloth tested and compared three colored solutions: MorphoColor interference sheets from Germany’s Fraunhofer Institute; ColorQuant interference encapsulants from the German company Lenzing Plastics; and diffuser films from Swiss-based Solaxess.

French CIGS specialist Solarcloth wants to integrate color into its flexible CIGS photovoltaic modules.

The company tested and compared three colored solutions: MorphoColor interference sheets from Germany’s Fraunhofer Institute; ColorQuant interference encapsulants from the German company Lenzing Plastics; and diffuser films from Swiss-based Solaxess.

The company’s CEO, Alain Janet, said this pv magazine France that the tested technologies were selected based on seven main criteria, namely yield degradation, the impact of color materials on the product and the environment, reliability, angular stability of the color, cost, the required inventory volume and the potential for scaling up to industrial scale .

“Colored PV is a fairly new playing field, where – so far – it has been difficult to find the balance between stability, costs in terms of industrial scale and customer expectations in terms of performance and visual appeal,” says Janet.

Fraunhoser’s MorphoColor solution is based on a stack of thin layers that allow an effect of successive reflections, interferences and diffractions that result in an angular distribution of color in space. The stack has a thickness of approximately 800 nm and can be deposited by pyrolysis spray onto a transparent polyethylene terephthalate (PET) substrate that can be integrated into the module between two layers of encapsulant.

“The efficiency losses generated are very low, on the order of 6% of the original cell efficiency, even for white or gray films. We observed very good color homogeneity and saturation when using a black backplate,” says Paul Rivas, a student of Nanoscience and Nanotechnology, who conducted the research in-house during his internship at SolarCloth. However, he explains that “the fragility of the PET substrate and the poor adhesion of the nanoprint tested in the spring have postponed its implementation until the end of 2024.”

Lenzing Plastics’ ColorQuant interference encapsulants have shown very good resistance between the used plates and on the used backing plates. “But there is a clear discrepancy between the colored plate on the front and the front plates that SolarCloth uses. In addition, the low saturation of the perceived color is not very pleasant and not very effective in hiding the cells,” says Janet.

The diffuser films of the Solaxess company, in turn, showed stable aging and good aesthetics. On the other hand, the device had poor adhesion performance and significant yield losses, “especially for light gray and white films.”

The MorphoColor interference plates from the German Fraunhofer Institute, with which SolarCloth has signed a development agreement, present the most promising results. “We are leaning towards this solution, subject to better adhesion and a competitive price for the MorphoFlex version,” said Janet, noting that the yields obtained are “very encouraging” and that the technique is “slightly more expensive, but reasonable” is. Once the solution has been validated, the modules are immediately ‘colored’ by SolarCloth.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.