Six Fraunhofer institutes develop new electrocaloric heat pumps that use elastocaloric heat lines instead of compressors to extract heat from the sources. The first pilot systems developed by the research team achieved an electrical efficiency of 99.74%.

The Fraunhofer Institute for Physical Measurement Techniques (Fraunhofer IPM) develops the German Fraunhofer Institute for Physical Measurement Techniques (Fraunhofer IPM) develops new States heat pumps that do not use compressors and are reportedly more efficient than compressor -based counterparts.

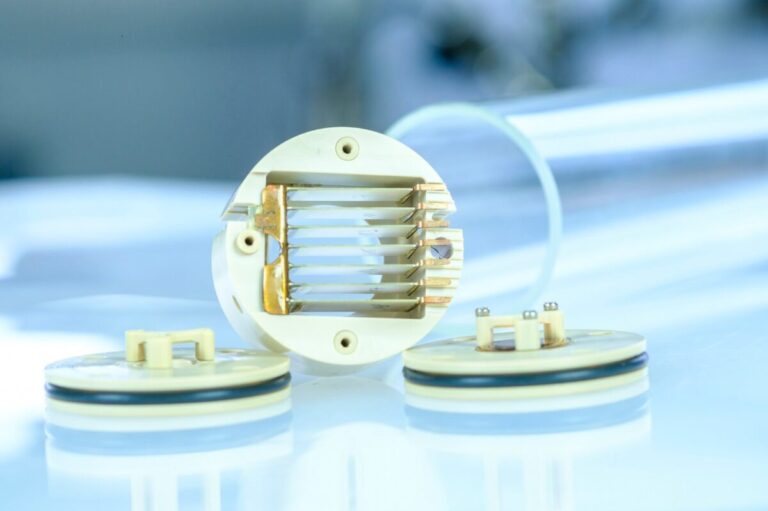

In conventional heat pumps, compressors Move the coolant through the cooling cycle and the heat exchanger to extract heat from the source. ROtary and scroll compressors are often used in commercially available heat pumps. Instead, the researchers used active elastocaloric heat pipes (AEH) to improve the heat transfer speed and to achieve latent heat transfer through the evaporation and condensation of the liquid on the calorie material, in which ethanol and water are used as fuels.

“The approach based on heat pipes ensures considerably faster cycle frequencies than conventionally active pumps of a liquid,” they explained. “The liquid must evaporate and condense on the surface of the electrocaloric material up to ten times per second. As a result, a lot of heat can be transported with little material, making it possible to build particularly cost -efficient systems in the future. “

The research team also used superhydrophilic layers developed by the Fraunhofer Institute for Electron Beam and Plasma Technology (Fraunhofer FEP) to make evaporation of the surface particularly efficient and a process to develop the electrodes of the electrocaloric segments in epoxy, which became it developed, developed. By the Fraunhofer Institute for Structural Durevality and System Reliability (Fraunhofer LFB), to prevent electrical malfunctions.

In addition, researchers from the Fraunhofer Institute for Applied Solid State Physics (Fraunhofer IAF) designed a multilevel DC/DC converter based on Gallium nitride (GAN) to improve the electrical controls of the heat pumps. The device reportedly helped the system to achieve an electrical efficiency of 99.74%, a value that it is said to determine this new worldwide standards in conversion -efficiency, because the efficiency was rather below 90%.

“In three different demonstrator systems, the researchers showed that all components function together, achieving the expected system performance,” said the Fraunhofer ISE, without more details about the pilot schedules. “According to simulations, the efficiency of electrocaloric heat pumps with the current materials is already the same as that of compressor systems.”

The new technology is part of Elkawe, shortly before electrocaloric heat pumps research, a research cooperation of six Fraunhofer institutions under the direction of Fraunhofer IPM.

“Elkawe has generated a jump forward in terms of material, electronic components and heat transfer. Although we still have a long way to go, these progress are promising steps to marketability, “said project manager Kilian Bartholomé of Fraunhofer IPM.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.