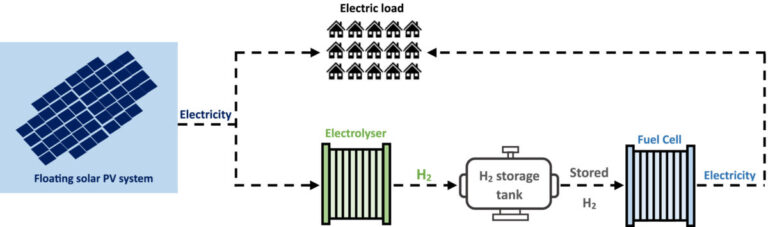

New research from Britain shows that Oman could use a floating PV farm at the Wadi Dayqah Dam to generate hydrogen. The scientist said the project is technically feasible, although only with advances in hydrogen storage technology could it become economically viable.

Scientists from the University of Exeter in the UK have explored the potential of installing a floating PV (FPV) farm on Oman’s Wadi Dayqah Dam and linking it to a hydrogen storage system.

Using various software programs to simulate and optimize the project scope, the researchers found that the project is technically feasible, albeit at a relatively higher levelized cost of hydrogen (LCOH).

“The proposed location for the FPV system is the Wadi Dayqah Dam, located in the northeastern region of the Sultanate of Oman, approximately 83 km southeast of Muscat in Qurayat,” the scientists said. “The reservoir, which covers an area of 350 hectares, is formed by two dams. The dam has an annual average global horizontal irradiation of 2,083.6 kWh/m2 and maintains a moderate average annual ambient temperature of 28.43 C.”

The researchers used the PVsyst software to build the FPV system. They identified an area of 130,000 m2 in the reservoir with minimal shade from the surrounding mountains. They then simulated the use of a bifacial monocrystalline silicon module with 635 W and an efficiency of 20.5%. The system cost was estimated at $1,260/kW, with an expected life of 25 years.

“Due to a lack of specific data on annual electricity consumption per household in Oman, an assumption has been made based on the average household size in Oman of 7.2 persons and the annual electricity consumption per capita in Oman of 8.274 MWh,” said the academics. “This calculation yields an estimated annual electricity consumption per household of 60 MWh/year. This figure was then used to determine how many households could meet their electricity needs with the proposed system.”

Image: University of Exeter, International Journal of Hydrogen Energy, CC BY 4.0

For the hydrogen storage system, HOMER Pro software was used to optimize its size with minimal energy costs. The scientists assumed they would use a proton exchange membrane (PEM) electrolyzer with a capital cost of $2,500/kW and a life of 15 years; a PEM fuel cell with a cost of $2,500/kW and a lifespan of 60,000 hours; a hydrogen tank that costs $1,000/kW and lasts fifteen years; and an inverter with a cost of $300/kW and 15 years respectively.

Regarding the storage system, the optimization tool indicated an optimal electrolysis power of 22 MW, a storage tank of 60,000 kg, a fuel cell of 13 MW and an inverter of 12.4 MW. “With an installed capacity of 26.57 MW, the FPV system includes 41,847 bifacial modules. The system demonstrates a specific production rate of 1947 kWh/kWp/year, resulting in a total annual energy production of 51,734 GWh/year,” the researchers said.

The entire system was found to generate 65,516 GWh of electricity annually, with the FPV system accounting for 79% of the total electricity production, while the fuel cell accounts for the remaining 21%. “The modeled system achieves a renewable fraction of 100%, demonstrating its ability to meet 100% of energy demand with renewable energy sources. The household electrical load consumes 25.3 GWh annually, which equates to 422 households,” the research team said.

The economic analysis of the system resulted in high levelized electricity costs (LCOE) of $0.97/kWh and LCOH of $29.7/kg, which is attributed to significant capital and operating costs associated with the large-scale system components and losses due to fuel cell inefficiency. . “Economic viability may be improved in the future with advances in hydrogen energy storage technology and rising fossil fuel prices,” the academics concluded.

Their findings were presented in “Investigating the integration of floating photovoltaic technology (FPV) with hydrogen (H2) energy for domestic electricity production in Oman”, published in the International Journal of Hydrogen Energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content