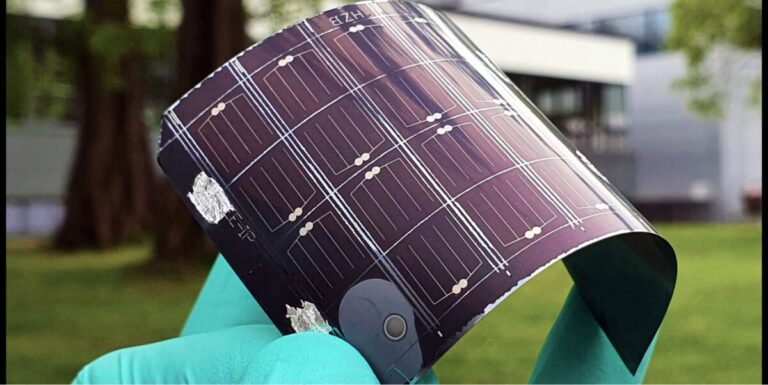

A European project aims to develop flexible tandem perovskite CIGS solar technology to create 25% efficient 100 cm2 modules with a variety of substrates for decentralized solar PV applications. The project involves the use of processes that are scalable for roll-to-roll production.

A European consortium is developing flexible tandem modules based on perovskite and copper-indium gallium diselenide (CIGS) for residential, commercial, vehicle-integrated PV (VIPV) and agrivoltaic applications.

The three-year initiative, coordinated by the University of Innsbruck, is known as Solmates, an acronym for Scaleable High-Power Output and Low-Cost Made-to-Measure Tandem Solar Modules Enabling Specialized PV Applications. It has €5 million in funding from Horizon Europe and will be launched in December 2023.

The 2-terminal monolithic tandem cells need to be fabricated on three types of flexible substrates: ultra-thin glass, steel and polyimide. The project requires roll-to-roll production processes.

The intended panel size for the project is 100 cm2 with an efficiency of at least 25%. The tandem cells with a narrow band gap CIGS bottom cell and a perovskite top cell shall be 1 cm2 laboratory scale devices with an energy conversion efficiency of at least 30%. Additionally, a “unique serial interconnect” will allow flexibility when it comes to module shape, size and output voltage.

“Four partners work on the bottom cell and four on the top cell. They use different preparation methods and have complementary expertise for preparing for different substrates,” says Bert Stegemann, project leader at the HTW Berlin University of Applied Sciences in Germany. pv magazine. “By having multiple PV suppliers in the consortium, we can leverage synergies and integrate various technological approaches.”

Launched just over a year ago, the Solmates group is working on optimizing the stack’s optoelectronic properties, handling the flexible substrates and deposition processes, and patterning all the layers required for the tandem structure.

“The first major milestones are planned for May 2025. These include life cycle assessment, process development for laser patterning and series interconnection, optimization of the perovskite bandgap and the development of recycling strategies,” said Stegemann.

A low-cost, roll-to-roll process is being developed that includes inline quality control. Such industry-compatible production methods position the technology for later scale-up. In addition, the work package includes a recycling strategy and an assessment of end-use applications that include environmental, social and economic benefits.

Participants include Germany-based materials company Solaveni, a subsidiary of Poland-based Saule Technologies, Italian perovskite startup Greatcell Solar Italia Societa ‘A Responsabilita’ Limitata (now known as Halocell Europe), Switzerland-based laboratory materials specialist Solaronix, and two Austrian-based companies: DePro Control, a supplier of vacuum deposition technology, and Sunplugged Solare Energiesysteme, a CIGS specialist.

In addition, the following research groups are participating: Helmholtz-Zentrum Berlin für Materialien und Energie and Humboldt-Universität Berlin, HTW Berlin University of Applied Sciences, Netherlands Organization for Applied Scientific Research (TNO), the British-based Oxford Brookes University, Semilab Felvezeto Fizikai Laboratory Zartkoruen Mukodo Reszvenytarsasag (Semilab) in Hungary, University of Rome Tor Vergata, University of Innsbruck, and Korea Institute of Energy Research (KIER).

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.