Scientists in the Czech Republic have conducted a techno-economic analysis of a green hydrogen production system powered solely by photovoltaics and wind energy. The system uses excess energy for water treatment and can achieve a levelized hydrogen price of $3.12/kg, according to its maker.

An international research team has conducted a techno-economic analysis to identify the optimal design and size of off-grid wind-solar power plants intended for green hydrogen generation at fuel cell electric vehicle (FCV) refueling stations.

The proposed system uses excess energy for electrocoagulation (EC), a method of treating wastewater. “To meet the water demands of industry and compensate for the lack of freshwater resources, EC was established to treat the discharged wastewater, which is environmentally friendly, especially when electricity is produced from renewable energy sources,” the scientists explained. “By integrating the EC station with a hydrogen production-based stand-alone renewable energy plant, sustainability and mobility can be improved.”

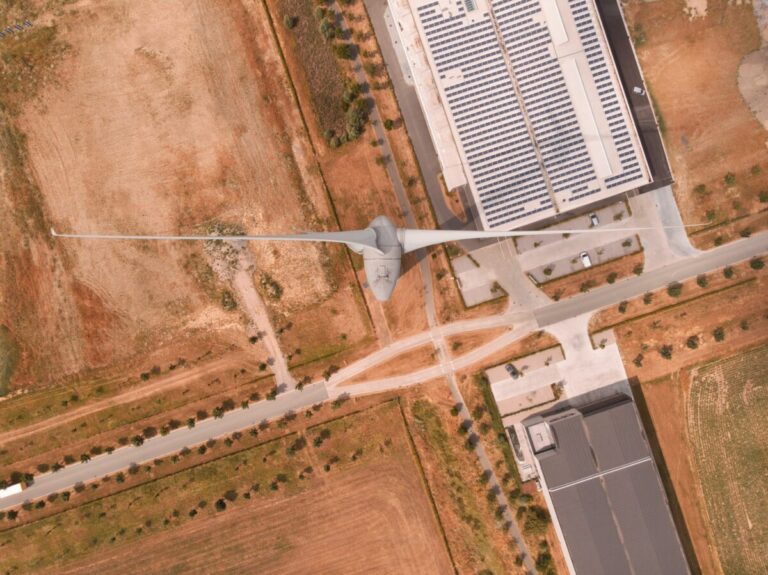

The research group assumed that the hydrogen station would be located in Ostrava, in the northeast of the Czech Republic. The city has an average solar radiation of 2.89 kWh/m2 per day and a wind speed of approximately 5.69 m/s. A hydrogen demand for the station is assumed to be 10 kg per hour or 240 kg per day. The proposed system consists of wind turbines, PV panels, an electrolyzer, an inverter, hydrogen tanks and batteries. They are all believed to have a lifespan of less than 25 years.

“The optimal design of the installation determines the size of the components as follows: photovoltaic panels with a capacity of 298 kW, 22 wind turbines with 100 kW each, 30 strings of 1 kWh lead-acid battery, electrolyzer with a capacity of 1000 kW and hydrogen tanks with a capacity of 800 kg,” they further explained.

Their analysis showed that the PV unit can generate up to 300,425 kWh/year and the wind turbine 6,697,566 kWh/year. The annual energy consumption of the electrolyzers is approximately 3,972,059 kW and their annual production is estimated at 85,595 kg. In addition, 262,678 kWh of electricity is generated annually for the electrocoagulation installation.

Through their techno-economic analysis, the academics found that the system may already be able to achieve significantly low price levels for the hydrogen it produces. “The levelized cost of hydrogen (LCH) is €2.89 ($3.12)/kg of hydrogen, while the net current cost (NPC) is €5.49 million, excluding the cost of the compressor unit,” they concluded. “The wind turbine and the electrolysis system have the highest NPC. Consequently, the overall NPC of the project and the LCH will be significantly affected by the growth or decrease in the corresponding costs of wind farms and electrolyzers.”

Their findings can be found in “An optimal stand-alone wind-photovoltaic power plant system for green hydrogen generation: a case study for a hydrogen filling station,” published in Results in technology. The research was conducted by scientists from the Czech VSB – Technical University of Ostrava, Egypt’s Menoufia University, Zagazig University, Cairo University and Kuwait University.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.