Scientists have designed a new control approach for water-to-water heat pumps that use carbon dioxide. They relied on a virtual heat pump for their tests. The coefficient of performance (COE) improved by up to 14.6%.

Scientists led by China’s Dongguan University of Technology have proposed a new control approach for water-to-water heat pumps that use carbon dioxide (CO2) as a coolant. The model-based optimal control (MC) was tested with a typical control mechanism (TC) via a virtual heat pump, improving the COE by as much as 14.6%.

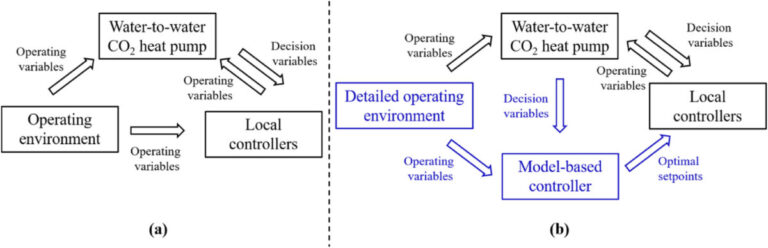

“An efficient optimization strategy for the MC of a water-to-water CO2 heat pump, aimed at reducing the computational burden, remains undeveloped. Therefore, this study aimed to develop an MC for improving the COP of a water-to-water CO2 heat pump by identifying optimal variables,” the group said. “System models were derived using extensive data from a virtual CO₂ heat pump whose reliability was validated prior to further simulations.”

The water-water CO2 heat pump included an evaporator (ET), a liquid receiver (LR), an internal heat exchanger (IHX), a compressor (CM), a gas cooler (GC), an expansion valve (EX) and two circulation pumps (PMs) . The TC uses fixed set points and simple control circuits to control specific parameters without regard to system-wide optimization.

To develop the more refined MC, the team built a virtual CO2 heat pump in MATLAB and REFPROP. 3,969 cases were operated to identify system models, which describe how the heat pump responds to changes in operating conditions. An experimental setup was designed to validate the system. This showed an average error of 4.4% for the gas cooler outlet temperature and 7.4% for the compressor power.

The scientists analyzed the thermodynamic behavior of the system components and developed an optimization algorithm to maximize COE by identifying the optimal discharge pressure and gas cooler outlet water temperature set points. They tested the system in three case studies for both the MC and TC models.

Image: Dongguan University of Technology, Case Studies in Thermal Engineering, CC BY 4.0

In the first case study, researchers set the inlet temperature of the evaporator mixture at 18 C and randomly set the gas cooler inlet water temperature between 29 C and 35 C. The target outlet temperature at the gas cooler varied between 40 C and 48 C. The MC achieved a 9.9% higher COP than the TC, with an average COP of 2.49 compared to 2.265 for TC.

In the second case study, the gas cooler inlet water temperature was set at 32 C, while the evaporator mixture inlet temperature ranged from 17 C to 19 C. The target gas cooler outlet temperature was varied randomly between 40 C and 48 C. The MC performed 8% better than the TC, with an average COP of 2.482 compared to 2.3 for TC.

In the final case study, the evaporator mixture inlet temperature ranged from 17 C to 19 C, the gas cooler inlet water temperature ranged between 29 C and 35 C, and the gas cooler outlet water temperature ranged from 40 C to 48 C. The MC achieved a 14, 6% higher return, with an average COP of 2,458 compared to 2,145 for TC.

“The system computation time with the multiplexed optimization strategy was reduced by 42.2% to 47.1% compared to the traditional optimization strategy,” the team said. “These results indicated that the formulated MC could effectively improve the energy efficiency of the water-to-water CO2 heat pump. The developed multiplex optimization strategy effectively reduced the computational burden and slightly reduced the average COPs. This study thus provided a guideline for the implementation of MC in water-to-water CO2 heat pumps, contributing to the improvement of COPs.”

They presented their results in “An investigation into optimal control approaches of a water-to-water CO2 heat pump for domestic hot water use”, which was recently published in Case studies in thermal engineering. Scientists from China’s Dongguan University of Technology, Guangdong University of Technology and Norway’s Norwegian University of Science and Technology jointly conducted the research.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content