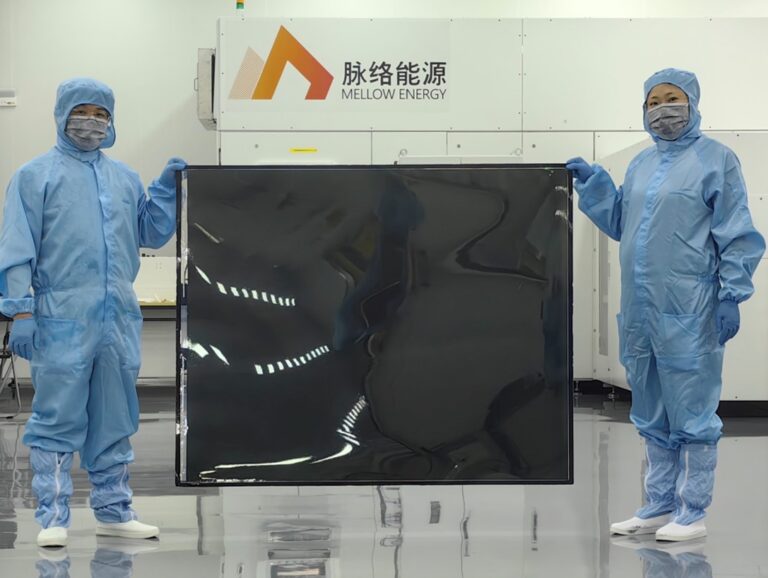

Mellow Energy claims its ML-Flex panel is currently the world’s largest flexible perovskite solar panel. The module is available in five versions with output power from 260 W to 300 W, measures 1,200 mm x 1,600 mm and weighs only 2.04 kg.

China-based perovskite solar cell and module manufacturer Mellow Energy, a spin-off of Jinan University’s Institute of New Energy Technology, has announced that it has manufactured what it claims is the world’s largest integrated flexible perovskite photovoltaic module.

“The ML-Flex module measures 1,200 mm x 1,600 mm x 1 mm and weighs just 2.04 kg,” the company’s CTO, Shaohang Wu, said. pv magazine. “It demonstrates the scalability of perovskite solar cells, a technology that is gaining increasing attention due to its high efficiency, lightweight properties and low production costs.”

“What makes this achievement even more promising is the wide range of potential applications for flexible perovskite photovoltaics,” he continued. “From wearable devices and wearable solar products to more advanced applications such as electric vehicles (EV), drones (UAV) and even building-integrated solar photovoltaics (BIPV), the versatility of this technology opens up opportunities across multiple industries.”

The new product is available in five versions with output power ranging from 260 W to 300 W and energy conversion efficiency from 13.5% to 15.1%. The no-load voltage ranges from 200 V to 205 V and the short-circuit current from 2.16 A to 2.26 A, with the fill factor between 60% and 65%.

The panels can operate within a temperature range of -40 C to 85 C and exhibit an operating temperature coefficient of -0.30%/C. They are equipped with a connection box with an IP68 rating.

“Our production line has a designed capacity of 100 MW for rigid modules and is also compatible with flexible module production. The line is currently in the phase of ramping up performance and capacity,” Wu explained. “Our large-scale production line can reduce production costs, improve scalability and further push perovskite technology toward widespread commercialization.”

“We recently came off the assembly line and are currently undergoing third-party efficiency certification. The certification results are still pending,” he further explained. “For flexible modules, stability testing has begun following recent production, while for rigid panels we expect to achieve IEC 61215 certification in June this year.”

A research group led by Wu last year unveiled a monolithic perovskite solar module based on an interconnection technique that reportedly prevents the outflow of volatile components from the perovskite solar cell absorber.

“In monolithic perovskite solar panels, the migration of ions in the junction region is a critical factor that affects both efficiency and stability,” Wu said. pv magazine at the time. “To address this problem, Jinan University and Mellow Energy have proposed an innovative method for generating ion barrier layers in situ, resulting in a substantial improvement in efficiency and stability. This gas phase treatment technique requires simple equipment, is easy to use and eliminates the need for additional coating processes, making it well suited for integration into production lines.”

The scientists fabricated the panel with an inverted perovskite cell based on an anti-diffusion layer, a substrate made of glass and indium tin oxide (ITO), a hole transport layer (HTL) made of polytriarylamine (PTAA), a 3D-2D perovskite absorber hybridized with PoBx species , an electron transport layer (ETL) based on a buckminsterfullerene (C60) and tin(IV) oxide (SnO2)and a silver (Ag) metal. They connected the solar cells together via P1, P2 and P3 writers.

The ETL was deposited on the perovskite absorber via atomic layer deposition (ALD) to inhibit the vertical escape of volatile species. They then applied after-annealing to improve the redistribution and recrystallization of the perovskite composition. The 2D/3D heterostructure aims to accelerate charge extraction at the perovskite/C60 interface and suppress photoinduced halide segregation.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.