Suzhou-based CPU Hydrogen Power Technology (CPUH2) has developed a 1.1 MW containerized hydrogen production system for alkaline water electrolysis.

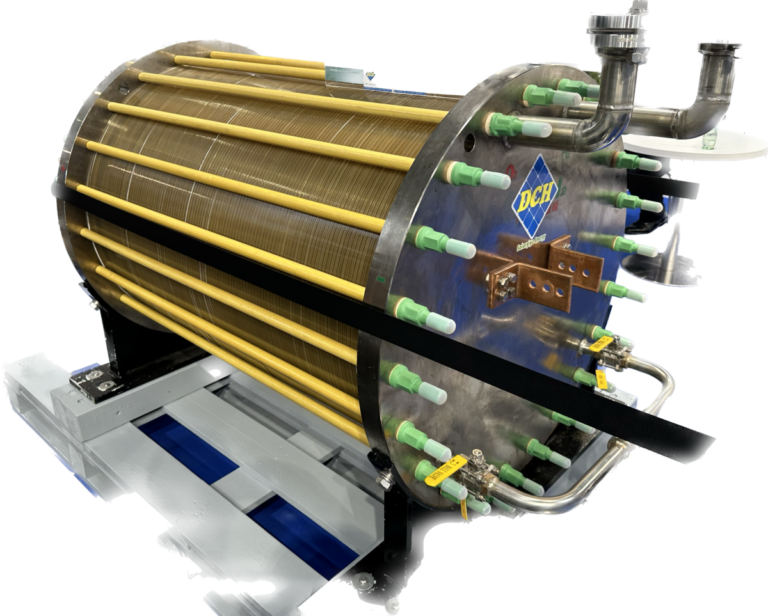

The system’s hydrogen production is 200 Nm3/h, or up to 428 kg/24 hours, with a purity of up to 99.999%, which CPUH2 claims can meet the demands of commercially available fuel cells. It consists of a rectifier, an electrolyzer, a liquid-gas separation system and a hydrogen purification system, in a standard 12.2 meter container.

CPUH2 says the system is tailor-made to provide a solution for distributed hydrogen production, coupled with renewable sources including solar power plants. It operates at a pressure of 1.0 MPa, over a power range of 20% to 100%. The total power consumption of the system, including all auxiliary equipment, is less than 58 kWh/kg.

The system will be marketed in Europe and presented at Intersolar 2024 by the German DCH Energy.

Ammar Falak Sher, Chief Business Development Office of DCH Energy, said pv magazine the system currently costs between $1.2 and $1.5 million. He added that the first project using the system in Europe will take place in Siegen, a German city in North Rhine-Westphalia, scheduled for the first quarter of next year. It will be powered by 3 MW of solar energy “so that will all be green hydrogen production,” he said.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.