A research team in Australia has used a lamination technique known as cold isostatic pressing (CIP) to build a perovksite solar cell based on a flexible double-layer electrode made of carbon and silver that can reportedly compete with gold-carbon-based electrode based counterparts in terms of efficiency. and stability.

A group of researchers led by CSIRO Manufacturing, part of Australia’s Commonwealth Scientific and Industrial Research Organization (CSIRO), has used a lamination technique known as cold isostatic pressing (CIP) to build a perovskite solar cell that uses a flexible double-layer electrode made of carbon and coated with silver (Ag).

CIP is often used to compress various types of powders for shaping components and semi-finished products. It applies isostatic pressure to a powder sample in all directions and is known for doing so producing semi-finished products with high integrity that exhibit little distortion or cracking during firing.

“CIP involves immersing a sample in a chamber containing ambient temperature liquid, liquid or gas, which is then isostatically pressurized,” the scientists explained. “The CIP lamination technique has been shown to apply very high mechanical pressure (up to 380 MPa) to form a seamless physical connection between the hole transport layer (HTL) and the carbon film, without damaging the device, without heat and without damaging the need for additional morphological adjustments to the carbon film.”

The 60 µm electrode was covered with a 20 µm silver layer and immersed in a water-filled CIP chamber at the set pressure for 30 s. According to the research group, this process could form a strong bond between the carbon layer and the HTL. “When the CIP pressure was applied, the thickness, morphology and conductivity of the coated electrode films changed,” it explains. “After applying pressure, both films were compressed, reducing the Ag film to about 16 µm and the carbon film to about 40 µm.”

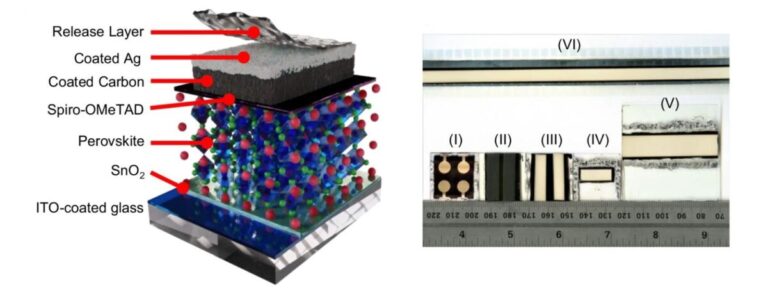

The academics built the cell with a glass-coated indium tin oxide (ITO) substrate, an electron transport layer (ETL) based on tin oxide (SnO2), a perovskite absorber, an HTL that relies on Spiro-OMeTAD, and the carbon-silver contact.

Tested under standard lighting conditions, the device achieved an energy conversion efficiency of 20.8%, an open-circuit voltage of 1.10 V and a short-circuit current density of 23.2 mA/cm2and a fill factor of 81.3%. These results, the scientists said, are consistent with those of reference devices built with more expensive, evaporated gold (Au) electrodes.

“The extreme pressure was combined with the advantages of a coated double-layer electrode consisting of carbon for soft interface contact and silver for high conductivity,” they further explained. “Therefore, performance loss was minimized for large-area carbon-perovskite solar cells, with record efficiencies of 19.8% and 16.9% for cell areas of 0.95 cm2.2 and 5.5 cm2respectively.”

The new cell design was introduced in the paper “A high-pressure isostatic lamination technique to fabricate versatile perovskite solar cells based on carbon electrodes”, which was recently published in communication materials. “These findings underscore the critical role of interface contact in improving the performance of carbon-perovskite cells, and the results pave the way for the development of low-cost, efficient, and reliable perovskite solar cells,” the researchers concluded.

Another research group at CSIRO recently claimed record-breaking efficiency in producing fully roll-to-roll printed, flexible solar cells. The researchers said at the time that the flexibly printed solar cells could be used in industries such as defense, emergency management, construction, agriculture, mining, space exploration and urban infrastructure.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.