A Chinese-Canadian research group has used a cadmium iodide doping technique for the first time to stabilize the sheet coating process in the production of solar cells based on formamidinium lead iodide (FAPbI3) perovskite. The academics built a cell that showed a significant efficiency improvement compared to an identical device without cadmium doping.

An international research team has produced a perovskite solar cell for the first time based on a cadmium-doped formamidinium lead iodide (FAPbI3) absorber.

FAPbI3 is one of the most promising perovskite materials for solar cell applications, as it offers a narrow energy bandgap and remarkable stability. “Given the advantages of FAPbI3 perovskite solar cells, it is now important to scale them up – a challenge that remains to be addressed given the FAPbI3 polymorphism problem and its hypersensitivity to manufacturing conditions,” the researchers emphasized. “We therefore hypothesized that the introduction of a homovalent Pb site additive would solve the problem. One such alternative is cadmium.”

The use of cadmium in the form of cadmium iodide (CdI2) is intended to stabilize the coating process of the blades at room temperature, which could otherwise cause the above-mentioned polymorphism problem, which depends on the environmental conditions and the humidity of the ambient air.

To investigate the potential effects of CdI2 doping, the research group first used the Compositionally Graded Film (CGF) optimization method, which produces a continuous combinatorial combination of all potential binary alloys. They created a FAPbI3 film with the CdI2 deposited throughout the film in varying concentrations, from 0% to 5%. The photoluminescence spectra (PL) were then measured using a compact spectrometer with a reflection probe.

“The PL intensity increased along the film, reaching the maximum intensity at l = 3.6 cm, corresponding to a concentration of approximately 0.6% Cd2+, and then gradually decreasing,” the academics explained. “The improvement of PL indicates the reduction of the non-radiative recombination rate in the perovskite film, which is beneficial for the performance of solar cells.”

The scientists then coated FAPbI3 films with different levels of CdI2 on indium tin oxide (ITO)/glass substrates. Using scanning electron microscopy (SEM) images, they found that at 0.6% cadmium, the size and density of grains reached full coverage, an important characteristic for films in solar cells.

Image: University of Victoria, Advanced Energy Materials, CC BY 4.0 deed

“We also assessed the stability of the films,” the group pointed out. “After aging in ambient air for 30 days at a relative humidity (RH) of 35%, the FAPbI3 film without Cd mainly showed the 𝛿 phase, while the optimal Cd-doped samples showed no sign of degradation. Thus, we conclude that Cd doping effectively releases the structural stress of the FAPbI3 perovskite and stabilizes the desired 𝛼 polymorph.”

The team designed the cell with a substrate made of glass and ITO, a tin oxide (SnO2) electron transport layer (ETL), the cadmium-doped FAPbI3 absorber, a hole transport layer based on Spiro-OMeTAD and a gold (Au) metal contact.

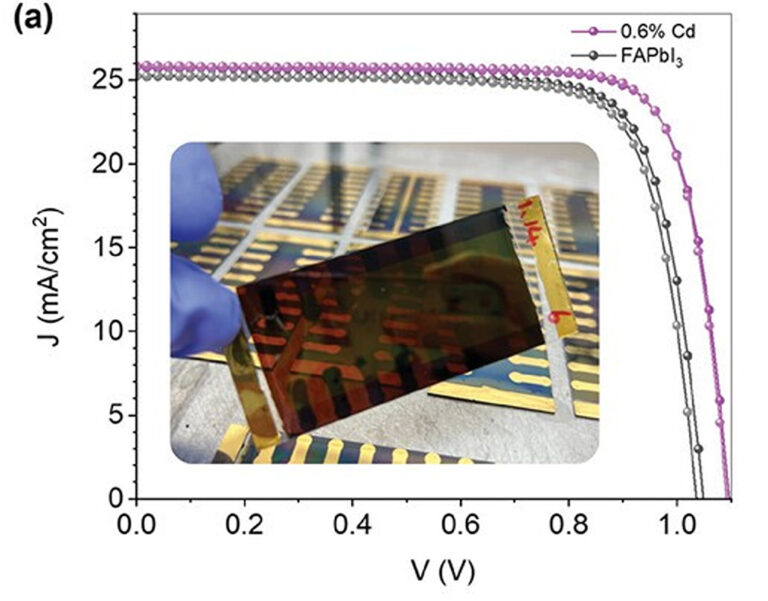

Tested under standard lighting conditions, the device achieved an efficiency of 22.7%, an open-circuit voltage of 1.10 V, a short-circuit current density of 25.9 mA/cm2 and a fill factor of 79.6%. A reference cell without cadmium doping achieved an efficiency of 20.8%, an open-circuit voltage of 1.05 V, a short-circuit current density of 25.2 mA/cm2 and a fill factor of 78.5%.

“Control FAPbI3 showed poor reproducibility due to the presence of pinholes, while more than 80% of target Cd-FAPbI3 showed efficiency above 20%. Solar cells with an active surface area of 0.9 cm2 with and without Cd showed a champion efficiency of 16.41% and 13.90%, respectively,” the scientists said.

Using Transient Absorption Microscopy (TAM), the academics also found that the target sample absorbs fewer charges and has a longer lifespan. “The trap states in the target sample are more easily filled, leading to increased charge accumulation and higher VOC.”

The new production process was presented in the study “Cadmium doping delays trap emptying in air-clad formamidinium-lead iodide-perovskite solar cells,” published in Advanced energy materials. The research group included scientists from Canada’s University of Victoria, the University of British Columbia and China’s Henan University.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.