British startup Futraheat has developed an industrial heat pump that can be integrated into existing factory infrastructure to provide high-temperature process steam.

“Unlike most heat pumps, which provide hot water up to around 80 degrees Celsius, the Futraheat heat pump can produce steam up to 130 degrees Celsius – essential for the brewing industry and believed to be a first for the UK,” a spokesperson for the company. pv magazine. “That is true compatible with PV.”

The Greeanstram system has a heat supply capacity of 300 kW to 1.5 MW and the well temperature can reach up to 200 C. The working fluids are R1233ZD and steam. The temperature coefficient (COP) is a maximum of 6.2

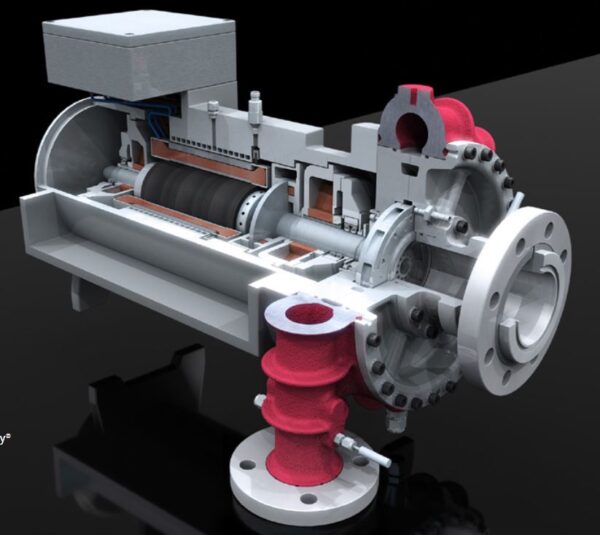

The core of the system is the TurboClaw centrifugal compressor which, according to the manufacturer, operates at lower speeds

without oil, resulting in lower production, operating and maintenance costs.

Image: Futraheat

The permanent electric magnet motor has a nominal power of 100 kW and a rotation speed of 20,000 rpm. “The compressor can increase the temperature by up to 60 degrees Celsius,” the spokesperson said.

The company recently deployed a 300 kW prototype at the Hepworth Brewery, based in Sussex, UK. “The brewery already has solar panels and it is part of their plans to use these to power the heat pump,” the spokesperson said.

Hepworth Brewery expects the new heat pump to reduce energy consumption and CO2 emissions associated with boiling wort by up to 90%, while cutting fuel costs by up to 40%.

The pilot project could be scaled up across the site to offset virtually all fossil fuel-generated heat used in the brewery.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content