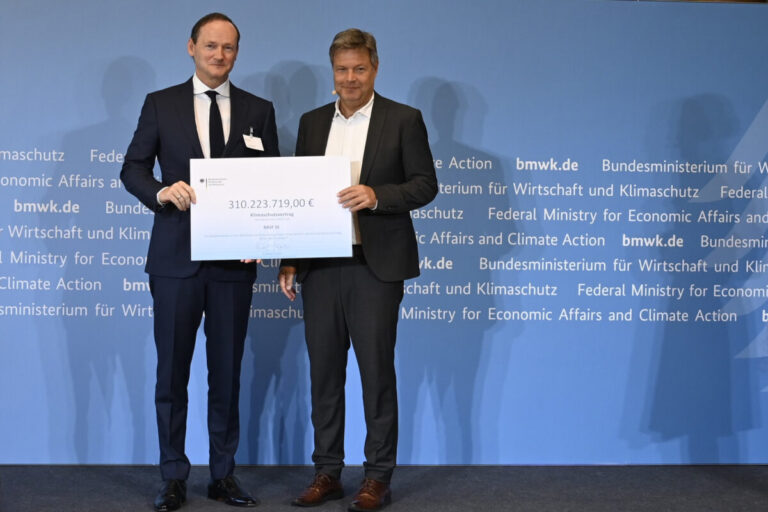

Robert Habeck, Federal Minister for Economic Affairs and Climate Action, presented the official notification of financing to Uwe Liebelt, President European Verbund Sites, BASF SE.

Image: BMWK / Andreas Mertens

The German Federal Ministry of Economic Affairs and Climate is providing German chemical company BASF with up to €310 million ($336 million) to build an industrial heat pump considered the most powerful in the world to date.

The planned heat pump will have a capacity of up to 500,000 tons of steam per year. It will use waste heat, generated during the cooling and cleaning of process gases in one of the two steam crackers at BASF’s Ludwigshafen site in western Germany, for CO2-free steam production.

Most of this steam will be used in the production of formic acid, and some will be supplied to other BASF production plants via the on-site steam network.

Following the approval of the financing, BASF now plans to commence preparatory construction work, with construction scheduled for the first quarter of next year. The factory is expected to be put into operation in 2027.

“Integrating new technologies into our chemical production processes is one of the most important components of the green transformation at BASF,” says Markus Kamieth, Chairman of the Board of Directors of BASF SE. “And our heat pump even has a unique selling point: the planned installation will be the first of its kind to be used for steam generation – there are no comparable industrial pilot projects anywhere in the world.”

BASF says the heat pump has the potential to reduce greenhouse gas emissions by up to 98%. It has set a target of achieving net-zero CO2 emissions by 2050.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content