US researchers have applied robotics and automation to the discovery of perovskite material for use in tandem perovskite solar cell technologies. The robotic platform is multifunctional and can perform precursor mixing, spin coating, annealing and characterization of the optoelectronic thin films.

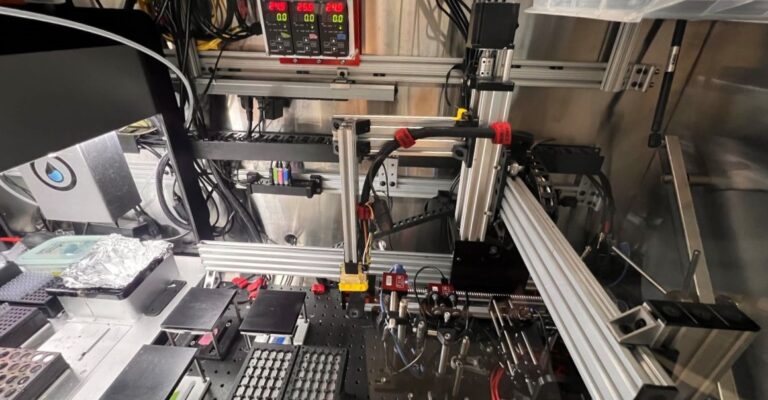

Researchers at the University of California San Diego have developed an automated material discovery and testing platform for tandem perovskite solar cell technologies. The robotic platform is multifunctional and can perform precursor mixing, spin coating, annealing and characterization of the optoelectronic thin films.

Initially focused on perovskite technology, it is called Perovskite Automated Spin Coat Assembly Line (PASCAL). It is suitable for compound engineering to improve the durability of perovskite absorbers for tandem solar cell applications, and for screening triple cation and triple halide compounds.

“We believe that having a robot perform repetitive tasks efficiently uses resources, freeing up well-trained researchers for higher-level tasks such as generating and testing hypotheses,” said David P. Fenning, corresponding author of the study. pv magazine. “It also reduces noise in experimental data, increasing the statistical power of experiments.”

The new platform reportedly enables a rate of up to 430 sample deposits or measurements per day. “PASCAL automates the fabrication of thin films following standard spin-coat procedures used in manual processes, albeit with precision, control and registration that exceeds that of human operators,” the researchers said.

PASCAL enables comprehensive compound screening and offers the ability to analyze 58 “unique compounds” within the complex domain of three-halide, three-cation compounds. It also supports the reproducibility of coatings, as evidenced by the team’s work.

“With this screening dataset, we use machine learning to develop a durable composition that exhibits almost no photoluminescence peak shifts under both 85 C and photoexposure at approximately 4 solar radii,” the academics said.

The composition was then made into a single-joint prototype. The characterization line contains cameras, LED and laser excitation sources, a halogen lamp and a spectrometer. It can generate a standard data set of darkfield, brightfield, photoluminescence and transmission data, stored for each sample.

The entire system is controlled from one computer using a custom Python library.

Looking at the results, the study confirmed the effectiveness of PASCAL specifically for the automation of solution-processed optoelectronic thin film research. The approach, hardware and data are “proof that automated platforms are an opportunity to accelerate the identification and discovery of new thin-film materials.” The accessibility of low-cost robotics and open-source automation communities was an enabling factor, Fenning noted.

The platform was presented in the study “PASCAL: The automated spin-coat assembly line for perovskite accelerates the composition screening of three-halide perovskite alloys”, published in Digital discovery.

Feedback from the industry and research community has been positive. “We’ve heard a lot of encouragement and excitement, from early-career researchers to highly experienced researchers, in both industry and academia. I think our most important contribution to them could be that it is not as difficult or expensive as it once might have been, given the advances in robotics and open source platforms that are available,” said Fenning.

Looking ahead, Fenning said: “Operational stability is the name of the game for perovskites. We are working on studies that connect sustainability with chemical and process variations, using PASCAL’s low-noise experimental base.”

He added that the PASCAL platform will support research to “scale up perovskite processing” at a new research center led by the Massachusetts Institute of Technology (MIT), which received funding from the US Department of Energy Solar Energy Technologies Office (SETO). It’s called Accelerated Co-Design of Sustainable, Reproducible, and Efficient Perovskite Tandems, called ADDEPT, a national center that includes university research teams from the University of California San Diego, Princeton, and MIT, as well as industry partners CubicPV and Verde. Technologies.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.