A pre-assembled conduit manufactured in Australia by Victoria-based balance-of-systems supplier PV Connections has reportedly reduced the installation time of rooftop solar systems by up to 20%.

Melbourne-based PV Connections says the pre-assembled Solarflex pipe could rupture solar system on the roof installation times up to 20%.

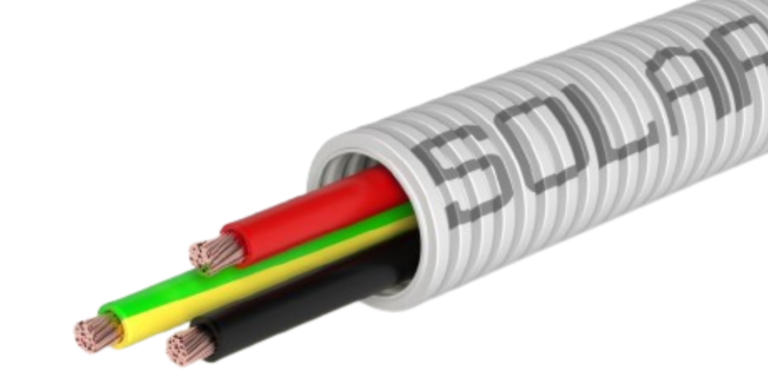

Designed to minimize the time required to connect the cable on site, the Solarflex is available in 60m 2mm x 4mm, 50m 2mm x 6mm and 30m drums. 4.4mm. They are all equipped with an earth cable, in a UV-resistant, corrugated, self-extinguishing tube.

PV Connections Director Rick Arkcoll said pv magazine the Solarflex dramatically reduces the time required to route multiple cables through a location installation.

“With this product you have one pre-wired conduit that you run from the roof, which is the best way because of the weight, through the roof cavity to the inverter in one go, and then it’s all done,” he says. .

“It makes things a lot easier on site, saving time and money as it is easier, safer and faster, minimizing the time it takes to be on a roof. It also has a pre-branded ‘solar’.”

Arkcoll said the products are manufactured in Melbourne and most components are also made in Australia.

“The conduit and earth cable are made in Australia and assembly takes place at our factory in Boronia, west of the Melbourne CBD,” he said.

The product appeared in 2014, following a change in standards that required the use of pipes in a roof space, and in the last twelve months has also been found suitable for underground use, including when immersed in temporary or permanent groundwater, allowing detached buildings to separately provide a space house. solar installation, such as on a garage, and inverter on a house.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content