With labor shortages that influence the solar segment on utility scale, some companies present the so-called robot “super employees” as a solution. The Startup Roboforce, which is based in California, ultimately wants to use a group of robot workers on the Moon, but for the time being the ambitions are more well-founded and they are aimed at solar developers who cannot find staff. Colleague-in the United States based Startup, Charge Robotics, does something similar.

“Roboforce is aimed at transforming the solar industry by using ‘Robo Labor’ to tackle labor shortages and improve productivity, especially in hard and demanding environments,” said the business development of the Startup, Veerstal Hardev.

The company started the year with a financing announcement of $ 10 million and the launch of its latest model on Intersolar North America 2025.

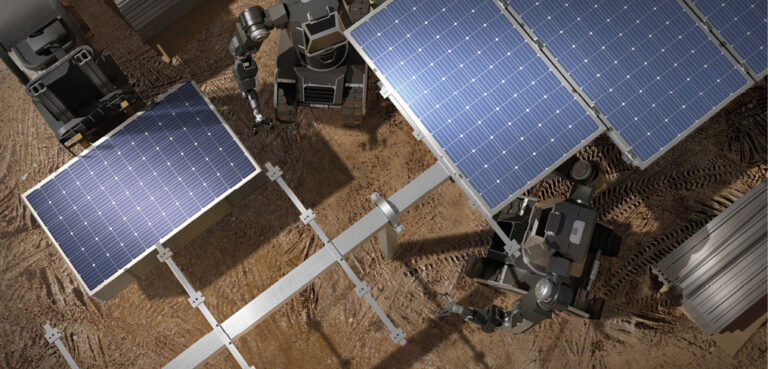

“With our first pilot projects that will be launched soon, and the recent Build of our mini-Farm zonnestest site, we want to significantly improve efficiency in the construction of solar energy,” Hardev said.

Golden chance

Hardev told PV -Magazine That he sees Solar as the first market in Roboforce and it is easy to see why. Industrial analysts have been marking labor shortages in the United States for some time. In a Q4, 2024 report, analyst Wood Mackenzie and Trade Body said the Solar Energy Industries Association that labor shortages will continue to influence the solar installations on utility scale.

A combination of labor shortages and inflation ensured that labor costs rise by 10% in 2024. In more recent reports, Wood Mackenzie has predicted that labor shortages in 2025 will continue to form a problem.

The American Bureau of Labor Statistics estimates that the employment of solar installers is expected to grow 48% from 2023 to 2033, much faster than the average for all professions. About 4,100 openings for solar installers are projected on average every year during that decade. Many of those openings are expected to be the result of the need to replace employees who transfer to various professions or leave the labor force, for example by retiring.

Hardev said those problems offer ‘a huge business opportunity’ for Roboforce. In September 2024, the company signed a memorandum of conformity with CT Green Capital to use its technology on the 1 GW of the developer, utility scale, for which about 3 million solar panels are needed.

CT Green Capital is just one of the many developers in the field of Nuts scale who turn to automation. On the other side of the world, Neoen Australia is currently testing artificial intelligence installer robots made by Chinese company, on its 350 MW Culcairn Solar Farm in Riverina, New South Wales.

Safety first

Two people who worked on that project said that the reason to use the robots had more to do with safety than labor shortages.

Judge for some comments PV -Magazine Has received itself from self-developers on Utility scale, but it is possible that high-tech evangelists such as Roboforce can overestimate the current possibility of the sun sector and indeed the appetite to fully automate the installation.

“Personnel has not been an important limitation for the project, since the Riverina region is dynamic, in terms of solar development, and an attractive place for people to live and work,” said Neoen’s spokespersons with regard to the Culcairn Solar Farm. “We first looked at the use of robots due to a safety and ergonomic lens, because the size and weight of modules have increased in recent years.”

The safety demand that results from the increasing robot implementation on sites is an important that should not get lost in the midst of the need for efficiency.

For the time being, Neoen is happy with the robots of the departure. “The main solution was the most advanced system; it was compatible with our modules and ready to be deployed,” said one of the spokespersons. “The robots have been deployed in recent weeks. While they have been trained AI, they are constantly adapting to improve efficiency. The trend we see on the spot is encouraging.”

American developer Aes Corp. chose to make his own robot. Maximo was launched in July 2024 and since then it has deployed more than 10 MW on four of the company sites, including the 2 GW Zonne-Plus-Storage factory in California.

Nicolas Riehl, head of the product for Maximo at AES, said that the company is expanding its fleet from Maximo Robots to support its 2025 installation goal of 100 MW.

Just like Neoen Australia, safety was a major factor in AES’s decision to use robot installers. As Riehl explained, crews that deal with the installation of the solar module “Lift and place hundreds of 65-plus pound modules daily, often in extreme environments such as desert heat.”

“Just like the use of an excavator instead of a shovel, Maximo makes the work less strenuous, which improves the working conditions for building coves and brings a new level of inclusiveness for solar jobs,” said Riehl. “A good example of this is that a few members of our crew were future mothers; together with Maximo they could safely participate in a segment of the workforce from which they would otherwise be excluded.”

Roboforce also works the safety corner as a sales argument for its robots, but it maintains a much more pessimistic view of the ability of developers to attract and retain human employees in the long term than all developers who were asked to comment for this article.

Assist or replace?

Hardev said that most competitors of Roboforce “are more as employee assistants where they help, and you still need human employees to do the fine, agile motor skills.”

“They do not remove the need to have employees repetitive, demand things,” Hardev argued. “Think of these large solar stands that are hundreds of megawatts, or a gigawatt in scale, there are millions of solar panels.

“Each of those millions of solar panels probably has four to six fixing points. You still need someone to do that kind of work by hand. If you leave more than 1 millimeter, it will not work.”

Roboforce develops its AI technology to self-learning, so that accuracy can maintain, regardless of products or environment with which it works. This included a lot of market research and the notice of all the safety restriction with which human employees were confronted.

Height was one, Hardev said. “When we visited sites, we saw boys on their backs doing work, trying to install close to the ground. It’s hard to do. And vice versa, sometimes they might have to get a ladder if it is much higher.”

Location is another factor, Hardev explained. “Depending on where the project is being built, there are certain considerations; if it is in a flood zone, mostly, at least in the United States, we see that the minimum ground clearance is about two -thirds of a meter off the ground. Our robot has a column where it can increase itself and it has long, industrial level so that it can be very high and very high.”

Roboforce -competent Maximo is also designed to be intuitive, albeit so that it can help employees, in contrast to replacing them. With the help of AI, Riehl and his team have shortened the time that is needed to train Maximo on new modules “from weeks to minutes”.

“This solution focuses directly on the barrier to quickly go from one project to another and keeps our fleet all year round,” said Riehl. “We wanted Maximo to be easy to record and easy for crews to be trained. We have developed and designed a state-of-the-art user interface and user experience and training program, so that crew members can be on board within a few days.

“We also develop a formal certification process for crew members to be certified to operate our robots. With safety in the top we work closely with EPCS on every construction site [engineering, procurement, and construction companies] And project owners to ensure that our activities meet the highest safety standards. “

Riehl said that he received positive feedback from the Union crews that have worked with Maximo on projects. “It was stated that working with Maximo was such a great experience that he does not want to go back to the traditional installation,” he added.

No silver bullet

Oana Penu is director of the European Institute of Innovation and Technology InnoEnergy Skills Institute of the European Union. She said that training staff to collaborate with robots in a safe, efficient way, the key to their successful implementation in the long term on sites in the field of Nutschalt.

“Robots are not a silver bullet,” she warned. “Without substantial investments in training for these collaboration rolls, we run the risk of replacing one staff shortage with another.”

She also pointed out that segments such as the roof and the residential solar energy are still very dependent on human employees. “Although robots can position panels, they are currently missing the possibility to perform tasks such as wiring, testing or problem solution. They are most effective on large -scale, flat solar farms. Installations on the roof and complex sites still require a lot of human work.”

From the technologist’s point of view, jobs in manual labor will usually be automated in the future. “We believe that while the next generation is coming, there is just no desire for people to do these kinds of jobs,” Hardev said. “So we think that this gap will be exacerbated over time. It is a big challenge and pain in industry.”

It is too early to say with certainty whether he is correct in all his predictions, but, as developers seem willing to confirm, it is true that robots can help relieve labor shortages and tackle safety problems on sites in the field of Nutshal.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.