Scientists in Egypt have created an anti-fouling coating for solar panels by mixing ethanol, deionized water, ammonium hydroxide and tetraethyl orthosilicate. They tested a coated panel outdoors for ten months and found that the panel exhibited a 64.7% higher current compared to reference modules without coating.

Researchers from Port Said University in Egypt have developed a self-cleaning hydrophilic nanocoating that can be used to reduce pollution and increase energy yield in PV systems in arid areas.

“Hydrophilic surfaces exhibit a water contact angle (WCA) of less than 90° and possess a high surface energy. These coatings attract water droplets and spread them in thin films over the panel surface. This thin film can act as a self-cleaning mechanism, sweeping away dust and dirt particles as the water surface evaporates,” the group said. “Our findings highlight the substantial potential of nanocoating for effective dust reduction, especially in dusty environments, improving the reliability of PV systems.”

To create the new nanocoating, the group used 50 ml of ethanol as a solvent, to which they added 1 ml of deionized water and 2.2 ml of 35% ammonium hydroxide. The mixture was poured into a glass bottle and heated to 50°C in a sand bath. After heating was applied, 2.5 ml of tetraethyl orthosilicate was added and the group stirred at 300 rpm for three hours.

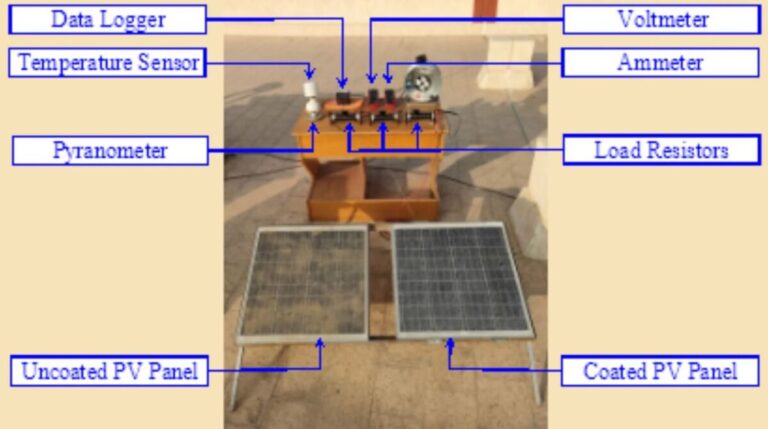

The mixture was then applied to a polycrystalline solar panel with a nominal efficiency of 13.71% and a maximum power of 60 W. Before the thin film was applied, the panel was first cleaned of all dust particles and then placed in a controlled environment where the coating was applied with a spray gun. This panel, as well as an identical reference panel without coating, was installed outdoors at a 30° slope in the city of Port Fouad, Port Said Governorate, Egypt.

Image: Port Said University, Scientific Reports, Conservation and Recycling, Common License CC BY 4.0

“The study, which was carried out in June, aimed to evaluate the impact of the coating on the overall performance of the panel. To ensure that the observed performance improvements are primarily due to the nanocoating, the control variables were carefully managed throughout the experiment by placing both the PV panels with and without nanocoating in the same location close to each other,” the academics said . said. “Solar radiation ranged from 120 W/m2 to a peak of 720 W/m2 around noon, while recorded ambient temperatures fluctuated between 23 C and 29 C.”

The measurements showed that the self-cleaning nano-coated thin film consistently increased the short-circuit current, on average 2.8 A, which is 64.7% higher than the 1.7 A of the uncoated panel. The coated panel also consistently achieved higher efficiencies, reaching peak values of 12–13.5. % compared to the 7–8% of the uncoated panel.

The test also showed that the output power of the coated panel ranged from 7 W to 38 W, with an average of approximately 24.75 W, while the uncoated panel showed an output power between 3 W and 23 W, with an average of approximately 14 W. .

“Despite these promising results, it is important to acknowledge the limitations of this study. The study was conducted at a single location in Egypt, and dust composition and environmental conditions may vary significantly in other regions,” the group concluded. “Future studies would assess the coating’s performance in different dusty environments. In addition, the long-term durability and cost-effectiveness of the coating require further research.”

The nano coating was introduced in the paper “Experimental investigation into the efficiency of a nanocoating for dust reduction on photovoltaic panels in harsh climatic conditions”, published in scientific reports.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content