Scientists in Australia have assessed 36 mobile inspection robots for PV plants mounted on the ground and have identified six commercial ground robots that are systematically used for this task. Their work presents the robots according to different species of the movement, navigation technologies, communication technologies and market status.

A group of researchers from Murdoch University in Australia has carried out an overview of all types of unmanned ground vehicles for the inspection of large-scale PV energy plants.

The scientists said that the land “robots” have different advantages compared to unmanned aircraft (UAVs) such as drones, because its use is limited in many countries and required skilled operators. In addition, UAVs cannot ‘read’ the back of PV modules and Balance of System (forest) components among modules such as cables and connectors or close-up images of the panels.

“Robots are generally free from these limitations. In particular, they have a good picture of electrical components such as PV cables, connectors (MC4), combiner boxes, inverters, switches and breakers, ”they also explained. “It is these items that run the most risk of overheating or boogen and causing a fire; PV modules themselves are rarely creating. “

Gemalen robots kunnen daarentegen de afbraak, schade en brandcomplexen in module -achterheets, scheuren in module achter glas, bungelende PV -kabels, beschadigde connectoren, losse moduleklemmen, roest- of beschadigde rekken en trackers volgen, aan de achterzijde van modules, hoge vegetatie, vogelnesten en dierlijke besmetting, vogelnesten en dierlijke vogels, vogels, vogelnesten en dierlijke Contamination, bundling, bundling water and moduling and modual erosion.

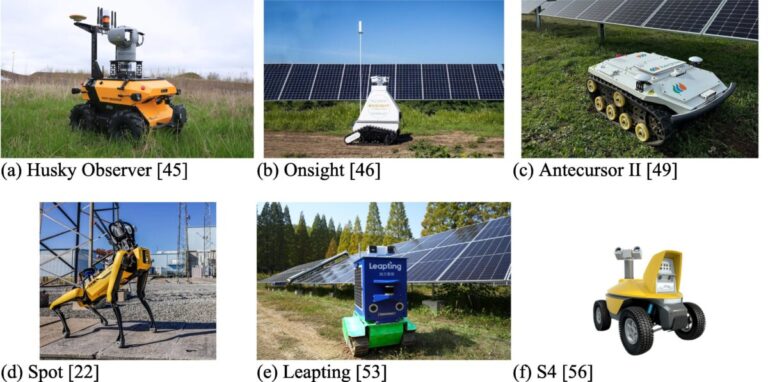

The assessment presents the ground robots according to different types of proceedings, navigation technologies, communication technologies and market status. “From mid-2024 we found six commercial ground robots that were systematically used for PV factory monitoring,” the academics said and noted that they initially assessed 36 mobile inspection robots. “Some were specifically designed for this task, while others were general platforms that were adjusted for it.”

Image: Murdoch University, Solar Energy, CC by 4.0

The six robots are: Husky Observer of Clearpath Robotics or Canada; Onsight from Onsight Technology, an American computer vision company; Antecursor II, a robot followed by Arbórea Intellbird in Spain; Boston Dynamics Spot, a quadruple, dog -like robot designed by Boston Dynamics; Year, a PV inspectorsobot developed by the homonymous Chinese provider; and S4, which is made by SMP robotics in the US.

Of the six robots, three tracks, two wheels and one legs use, where the latter is the most agile solution, although they are also labeled as “relatively inefficient, complex and expensive.” Tracks are recommended for both rough and soft terrain, while wheels are said to require relatively smooth and sturdy soil.

The research group indicated that the market status of PV inspectors’ robots can be considered ‘near-commercial’, because proof-of-performance is underway. “Technical performance, reliability and economy still have to be validated by means of full and long -term use,” they explained further.

“Concluding, autonomous robot inspection of solar farms is an emerging technology that is probably a supplement to the air surveys,” emphasized the group, “emphasized the group.” Robots are especially suitable for detecting hotspots in PV -electric systems – valuable and advanced images – and getting rid of detailed and gaining “

The research work is available in the paper “Assessment of unmanned soil vehicles for PV -factory inspection“Which was recently published in Solar energy.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content