It was a time of video cassette recorders (VCRs) and Walkmans and the first Apple Mac. The trade in household appliances was booming and everyone wanted a Crock pot. The 1980s were also a time of growing international trade and an era in which making economic policy more market -friendly. This resulted in increasing number of electrical products that were sold across borders, so that the need to ensure that they were safe and tradable. This is why, in 1985, the IEC conformity assessment system for electrical equipment and components (Iecee) was born.

“Globalization and international trade were enormous driving forces,” says executive secretary of Iece Wolfram Zeitz. “Because manufacturers wanted more and more access to global markets, they needed a system that harmonized the hundreds of different requirements in different countries. The IECE Certification Body (CB) schedule stipulates that, with the potential for one test and one certification to meet global requirements. “

A few facts and figures

Now, forty years later, IECEE has grown into one of the world’s most recognized and trusted multilateral certification systems based on international standards, which deliver more than 120,000 certificates every year. The CB schedule comprises 596 test laboratories with more than 15,000 manufacturers who use it.

Members of Iecee include 53 participating countries and 94 National Certification Bodies (NCBs) that use the principles of mutual recognition and mutual acceptance of test results to obtain certification or approval at national level all over the world. This means that manufacturers and consumers can be assured that certified products meet the requirements of international standards and are therefore safe and performance. Trade barriers caused by different certification criteria in different countries are therefore reduced.

A journey through the memory strip

The roots of Iecee steal back to 1926 when the world struggled with the installation of electricity and electrical equipment and there was a need for a harmonized picture to ensure its safety and functionality. After the Second World War it became reborn as a European conformity assessment system, Cee. Cee acknowledged the reach and power of IEC international standards in the sector and joined forces with the IEC in 1985 to create Iecee.

Iecee was born out of a market need, and it is a principle that has guided its evolution evers evolution, says conformity assessment operations manager Tara Mitchell, who has been with the organization as office officated to the ign00. Has Given Rise to a Greater Need for Trusted Products, So We Are Constantly in Touch with Industry Experts and Policymakers to Ensure We Can Offer The Services That The Market needs. “

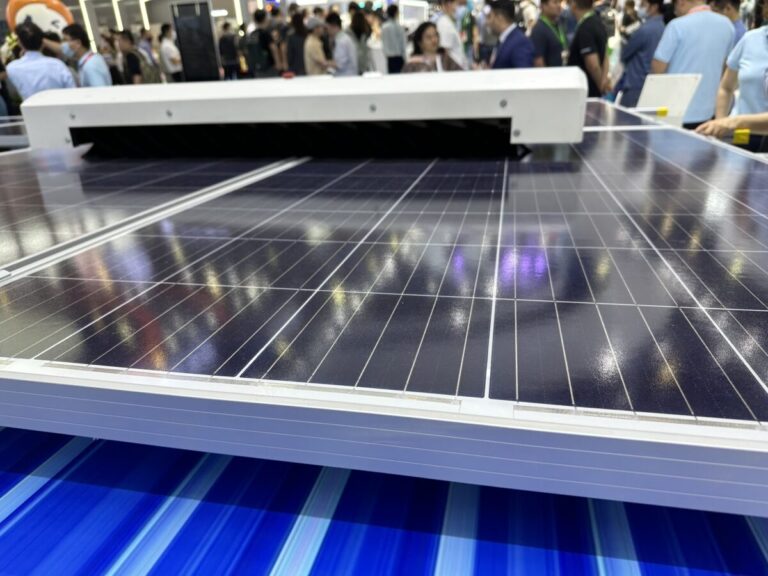

Move with time: Solar PV panels

This meant the expansion of his assignment for specific industrial programs, such as those for photovoltaic (PV) -Panels for solar energy, introduced in 2003, which offers access to qualified test laboratories for the certification of PV components and modules in accordance with the relevant IEC. IECEE PV certificates To the fact that all elements and components have been designed, manufactured and tested according to IEC International Standards, which means that they will meet quality and safety requirements worldwide. They offer manufacturers of PV installations with a simple and reliable way to identify the components with which they can build high-quality PV products and systems.

From batteries to energy efficiency and cyber protection

Other programs followed, including one for batteries that test for their safety, performance, component interoperability, energy efficiency, electromagnetic compatibility (EMC) and hazardous substances; The electrical energy efficiency (E3) Program to support the efforts of the industry to develop energy -efficient products and adding categories of standards such as electric vehicles and industrial automation.

Functional safety is another more recent working area, essential for smart production, as well as cyber protection. The IECEE Cyber Security Certification Program looks at industrial automation and operational technology using the IEC 62443 series. To supplement this, IECEE recently included a European Telecommunication Standards Institute (Etsi) Standard devices in the program to support Internet of Things (IoT). The program is intended to offer manufacturers a way to cut through the increasing number of national rules and regulations on cyber protection, in particular those in various areas of law, dealing with international trade and managing supplement chains.

Looking at the future

Chairman Simon Barrowcliff says that although the CB schedule and testing and certification for the 23 categories of electrical and electronic products remained the core of its activities, Iecee consistently investigated new activities where necessary. “The demand for third -party certification is still as strong as always, especially in a world where trust is sometimes difficult to come by”, volunteer work.

“But we are agile enough to expand our services to remain relevant. An example of this is the new certification of personnel competencies (COPC) schedule with its first competence area aimed at supporting safety in the production industry. “Based on ISO/IEC 17024The schedule offers certification agencies for personnel competence (CBPCs) the possibility to assess the competence of those who work in different industrial sectors to ensure that they have the necessary skills and knowledge to use, manage, repair, maintain or communicate with machines in a safe manner.

It also offers industry a reliable benchmark of what is considered ‘competent’ all over the world. For production this includes aspects such as management, design of installations, equipment selection, inspection, maintenance and repair. Although the schedule starts with certification with regard to machine safety, it is intended that other competence areas will be added according to market needs, with already identified functional safety and cyber protection.

Barrowcliff says it is people and their expertise who have been behind the success of Iecee. “In the past 40 years we have had a constant stream of expertise in the system thanks to our strong network of experts around the world,” he explains. “What is more, our management structure, which includes peer assessment and mutual recognition, ensures that certificates and test results can be trusted because it is in everyone’s interest for the system to work effectively. With our growing reach and recognition, IECEE has become a reliable way to guarantee safety and reliability, which is not easy in an increasingly globalized world, “he concludes.

Author: Catherine Bischofberger

The International electrical engineering committee (IEC) is a global, non-profit membership organization that brings together 174 countries and coordinates the work of 30,000 experts worldwide. IEC international standards and conformity assessment are based on international trade in electrical and electronic goods. They facilitate access to electricity and verify the safety, performance and interoperability of electrical and electronic devices and systems, including consumer devices such as mobile phones or refrigerators, office and medical equipment, information technology, electricity generation and much more.

The views and opinions expressed in this article are the author, and do not necessarily reflect it by PV -Magazine.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.