A Qatari research group has analyzed the performance of polyethylene terephthalate backing sheets in real outdoor test conditions in desert areas and identified the main causes leading to degradation. These include prolonged exposure to high ultraviolet radiation, high operating temperatures and relative humidity.

Researchers from Hamad Bin Khalifa University (HBKU) in Qatar have conducted an assessment of the degradation of polyamide (PA) and polyethylene terephthalate (PET) backsheets used in PV modules installed in desert climates, where solar radiation and ultraviolet (UV) ) radiation have an influence. approximately 50% higher compared to non-desert environments.

The analysis focused on the origin, propagation, chalking and delamination of the backplate. “In this study, extensive research was done on PA and PET chalk powder to gain a better understanding of the failure mechanism and powder composition,” the researchers specify.

The tests were carried out at HBKU’s Outdoor Test Facility (OTF) in Doha, where in summer months the monthly average ambient temperature is 31 C, the average module temperature is 38 C and the relative humidity (RH) is approximately 50%, while in winter months these values are 40 C, 70 C and 65% respectively.

“Furthermore, a high surface albedo of 40% was measured at the OTF,” the group explained. “This high albedo value is expected to enhance the UV radiation received at the backplane of the PV module due to multiple scattering of the reflected radiation.”

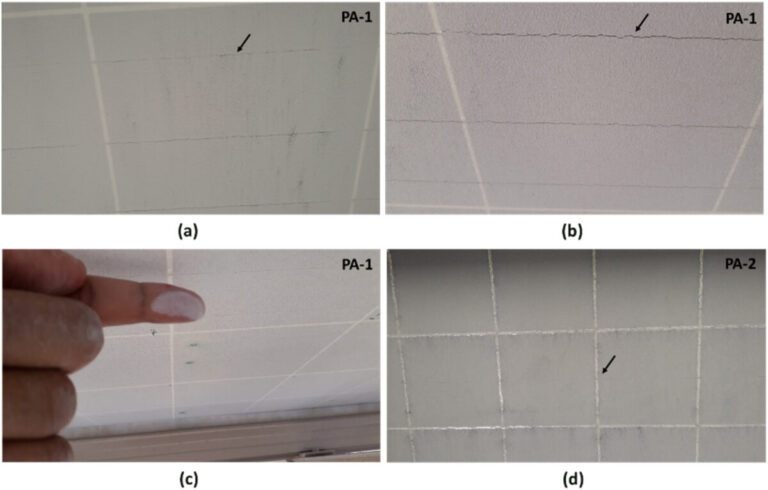

Ground-mounted radiation sensors were used to measure solar radiation, ambient air temperature, and relative humidity. The PV system included two types of coextruded PA-based backsheets, named PA1 and PA2, and two types of PET-based backsheets, named PET1 and PET2. Through a scanning electron microscope (SEM) and energy dispersive X-ray spectroscopy (EDS), the group analyzed powder collected from affected backing sheets.

The analysis revealed that the main driving forces behind backsheet failure were the combination of high operating temperatures, thermal cycling, relative humidity and prolonged exposure to UV radiation.

It also showed that all 48 PV modules with PET-1 and 8 modules with PET-2 showed backsheet degradation, with the PET-1 samples showing crack propagation and high crack density and PET-2 samples only showing chalking without cracks in the backsheet. “The elevated temperature measured at the junction box was found to increase the yellowness of the PET-1 backsheet, resulting in the loss of tensile strength of the backsheet material,” the academics explained.

They also found that the PA backsheets had green spots composed of antlerite, a greenish hydrous copper sulfate mineral, and said the presence was due to the reaction of the PA-1 chalk powder with the solar cells’ interconnections.

Their findings are available in the study “Degradation of the backplate materials of photovoltaic modules in desert climate”, published in Solar energy materials and solar cells.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.