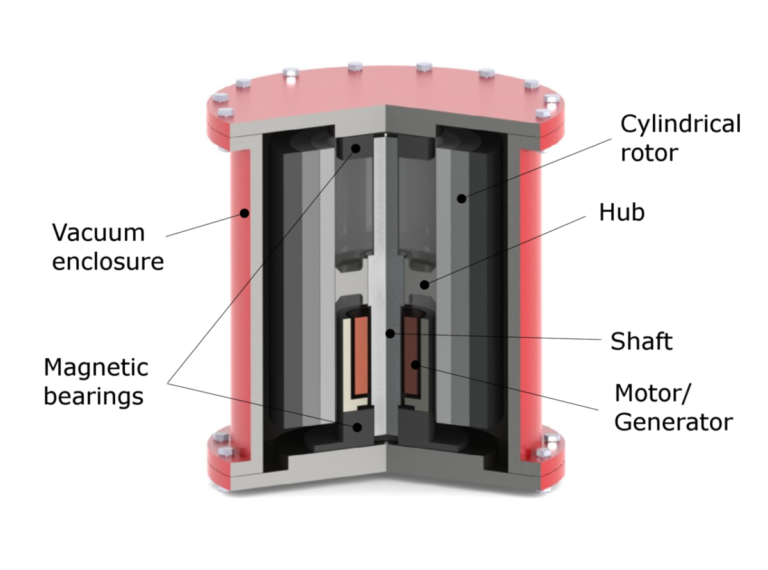

Main components of a typical flywheel

Image: Pjrensburg, Wikimedia Commons

By ESS news

China has connected its first large-scale standalone flywheel energy storage project in Changzhi city, Shanxi province.

The Dinglun Flywheel Energy Storage Power Station started operations in July last year. China Energy Construction Shanxi Power Engineering Institute and Shanxi Electric Power Construction Company carried out the construction work. BC New Energy was the technology provider and Shenzhen Energy Group was the main investor.

The facility has a capacity of 30 MW and is equipped with 120 high-speed flywheel units with magnetic levitation. Every 10 flywheels form an energy storage and frequency control unit, and a total of 12 energy storage and frequency control units form an array, which is connected to the electricity grid at a voltage level of 110 kV.

The project represents a pioneering use of a semi-buried underground pit system, designed to provide a safe environment for the operation, waterproofing, cooling and maintenance of the flywheel unit.

Flywheel energy storage technology is a form of mechanical energy storage that works by accelerating a rotor (flywheel) to a very high speed and retaining the energy in the system as kinetic energy. Compared to other mechanical energy storage technologies such as pumped hydro and compressed air, flywheel storage has higher energy and power density, higher efficiency and fast response.

To read further, visit our ESS news website.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content