U.S. solar energy production is growing astronomically, and while it is leading the way in electrifying the U.S. power grid with renewable energy, the technology isn’t built to last forever. Solar panel recycling services are currently in demand, and a few notable companies have already set up factories in the United States to process tens of thousands of damaged or otherwise unusable modules.

That demand will undoubtedly grow over the next decade as projects built in the late aughts begin to reach the end of their lives, and as installations have only increased since then, so will the number of solar panels removed.

“Unfortunately, I think a large percentage of panels in the United States are still being landfilled,” said Steven Turk, CFO of SolarPanelRecycling.com. “But more and more companies, for their ESG goals and other reasons, are starting to recycle.”

Even if they are damaged or at the end of their life, there are materials in the solar panels that can be recycled back into the supply chain. But it has taken some time and ingenuity from the recyclers who created this market to extract them properly.

Formalizing the recycling of solar panels

Three years ago, Suvi Sharma left his role at solar panel manufacturer Solaria to study circular supply chains and economies. After exploring recycling in various industries, he turned his attention back to solar energy and co-founded it Solar cyclea crystalline silicon solar module recycler with two operating facilities in Odessa, Texas, and Mesa, Arizona, and a third on the way in Cedartown, Georgia.

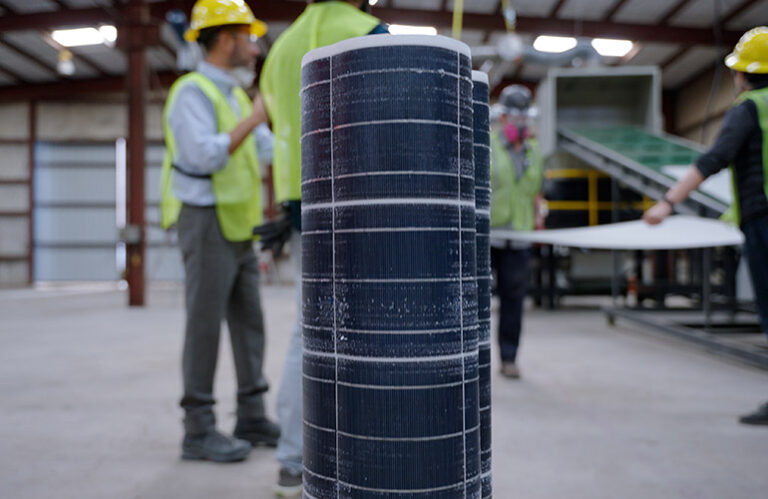

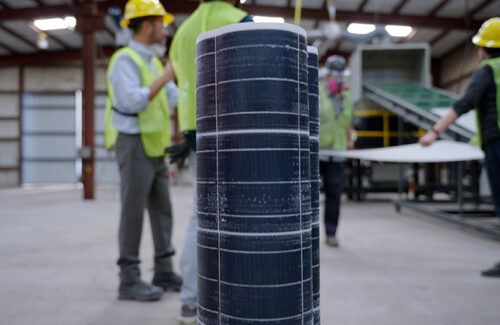

Stripped solar cells are rolled up and awaiting further processing in a SolarCycle facility.

“We had made phenomenal progress in making solar panels more efficient and cheaper, deploying more PV systems and financing them, but we had not yet figured out how to recycle these end-of-life panels and provide a could create a circular supply chain.” Sharma said. “When I started looking into why that is, it was because we needed to develop the technology to do this at scale. When you go to a solar panel manufacturing facility, you see equipment processing materials you don’t see anywhere else, right? Because it is highly specialized. We need to do the same for recycling solar energy – for ‘dismantling’ these panels.”

Since its inception, SolarCycle has processed modules from all 50 states and other territories in North America.

SolarPanelRecycling.com (SPR) is a subsidiary of legacy electronics recycler Powerhouse Recycling. Powerhouse started recycling PV after a utility customer came to the company with a decommissioned large-scale solar project. After establishing its own solar energy recycling measures, SPR was founded almost 18 months ago.

With support from Powerhouse, SPR has four processing plants: two in Salisbury, North Carolina, a glass processor outside Atlanta, Georgia, and a fourth plant in Breckenridge, Texas, opening soon.

Solar contractors, developers, equipment distributors, or other entities with a load of panels that need to be disposed of, hire recyclers to handle logistics and transport the panels to a regional processing plant. Solar energy recycling customers are typically national companies with large installation areas and large inventories to be recycled, rather than smaller individual residential contractors.

Recyclers build processing plants in regions where there is a demand for the purchase of waste solar panels. SolarCycle deliberately located its processing plants in the southern states due to their proximity to most major solar energy installations. SPR will even open a new factory if necessary in addition to a large enough decommissioning or repowering project.

“For solar owners who are concerned about capacity, I don’t think this is really a big deal because if someone were to come to us and say, ‘we have a large facility that needs to be restarted or that had a weather event, and we have hundreds of thousands of panels there,’ well, it would be economically beneficial at that point if we just built a facility nearby,” Turk said.

Being close significantly reduces transportation costs and makes it less likely that someone will decide to send the modules to the landfill.

Avoiding the landfill

Despite being inherently green in their operation, certain types of solar panels can be considered solid or hazardous waste due to the presence of lead and cadmium telluride, and several states have banned the technology from entering their landfills. Disposing of solar panels in any capacity comes at a cost, and while not yet quite comparable to the costs of landfilling, solar panel recycling services have both an environmental and economic benefit.

Solar panels are fed into a processing machine at a SolarPanelRecycling.com facility. The materials extracted from solar panels are sold to willing sellers and returned to the supply chain.

First, these panels do not sit in landfills indefinitely. The majority of extracted materials can be returned to the supply chain. Each make and model of solar panel will have slight differences in components, but they are largely the same and consist mainly of glass, a metal frame (often aluminum), silicon, copper and silver.

“The problem is that we can’t just throw an entire solar panel into the shredder and get a usable product, while that is possible with printers and other devices,” Turk says. “So the real difficulty in recycling solar energy is to somehow eliminate the challenge of this contamination that occurs in the encapsulant.”

Encapsulant bonds the internal elements of a solar panel together, but if not removed properly it can contaminate surrounding components. Recycling solar panels begins with removing the junction box and metal frame, then shaving off the glass so that the encapsulant does not attack the silicon solar cells. Then the rest of the panel is crushed and shredded, and the precious metals contained within are extracted. The materials are filtered and pass through airtightness and electrostatic separation chambers for cleaning.

These cleaned and separated elements are returned to the supply chain and sold to various suppliers. Recycled glass is often reused in fiberglass insulation, and SolarCycle will soon make new glass for solar panels using recycled materials processed at its Georgia facility. Metals are easily recyclable and are reused in many different products.

Industry analysts expect solar panel production to dominate a fifth of the global silver supply by 2030, so Sharma believes some of the silver recycled today will end up back in solar panels. For materials like silicon, recyclers hope to eventually supply that back to PV manufacturers to create a fully recycled, household solar panel.

“If we do this right, the way we’re trying to, we can make solar the most circular industry in the world,” Sharma said. “The solar panel product itself, the fact that it’s primarily glass and metals, and the fact that these big solar companies, most of them, are very forward-thinking and forward-thinking and really looking at how they can create a sustainable industry in the long term create.”

How are panels damaged?

Despite having a lifespan of about three decades, solar panels are not invincible. They are mainly made of fragile glass.

There are a few reasons why solar panels are sent to recyclers:

- Manufacturing defects

- Installation, construction or transport damage

- Operational and maintenance losses (warranty issues)

- Damage due to weather conditions

- Strengthen projects again

- Decommissioning projects

Palletized solar panels await recycling in a SolarCycle warehouse.

The companies reported that among this group, decommissioning is the smallest contributor, but Sharma said he expects project decommissioning to eventually match installation numbers as more large solar projects reach end of life. Currently, the largest inventory of recycled panels from both SolarCycle and SPR comes from construction disruptions, followed by weather damage.

“I think the reason for that is because so many are being installed right now,” Turk said. “Even if the percentage damaged during installation is small, you’re still talking about hundreds of millions of panels going in, so it becomes a big part of the power.”

Weather damage is another source of broken panels for recyclers as the frequency of severe climate events has increased. That was the case in 2024 alone 15 reported weather events causing more than $1 billion in damage in the United States.

Drawing a circular supply chain

There is still much to achieve in the field of solar panel recycling. SolarCycle recently built a 500 kW solar project consisting entirely of retired solar panels, powering 50% of its Odessa, Texas facility. The company is investigating how cadmium telluride panels, manufactured primarily by First Solar, can be recycled and ways to remelt and reuse recycled glass for use in new products.

“There are no crystalline silicon module solar glass factories in the U.S. that we can send it to, so we do it ourselves and vertically integrate downstream into the material production,” Sharma said. “That’s a tough ask from an operations and capital intensity perspective, so that’s a big focus for us in really closing the loop and creating a circular solar supply chain.”

And SolarPanelRecycling.com is preparing to open its newest facility in Texas, plans to open another within a year, and is ready to launch new regional operations across the United States as demand dictates.

As their services expand, solar recyclers hope they can match and eventually beat the price of going to landfills. This way they can get one step closer to making this technology as green as possible.