A group of researchers have investigated how high-temperature heat pumps can be scaled up for industrial applications and have found that larger setups promise higher efficiency. They also found that smaller setups show a better coefficient of performance due to design effects.

A European research team has investigated the scale-up effects of high temperature heat pumps (HTHP) using the refrigerant R1233zd(E) and found that their size is a key factor in the coefficient of performance (COP).

In particular, the group compared the performance of two laboratory-scale HTHPs with different capabilities to make valid general statements about the challenges of scale-up. “It should be noted that the study focused on reciprocating compressors. The scale-up behavior of other compressors remains to be investigated,” said the corresponding author Jaromir Jessberger told pv magazine.

“Studies typically focus on a single experimental facility and validate the measured experimental results using simulation models or literature data,” the researchers said. “Nevertheless, given the significant disparity between these experimental setups and industrial-scale operations, an important research question arises regarding the feasibility of directly scaling up the laboratory results to greater thermal capacity.”

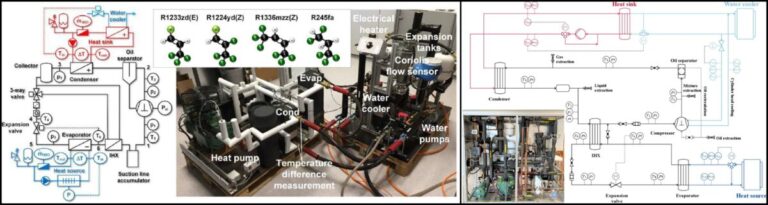

The research group compared two HTHPs designed in previous literature, one with a thermal power of 11 kW (HTHP A) and the other with a thermal power of 35 kW (HTHP B). They analyzed both the heat transfer characteristics, the heat loss in various components, the compressor coefficient and the coefficient of performance (COP).

“The heat pumps examined show a high degree of similarity in components, such as a Bitzer reciprocating compressor, plate heat exchangers and oil separators, allowing a thermodynamic comparison between the two,” the academics said. “They both have a heat pump cycle with reciprocating compressor and internal heat exchanger (IHX).”

Through their analysis, the scientists discovered that more elaborate setups promise higher efficiency. “The pinch points and temperature shifts can be affected by the relative size of the components; The scale effects, such as 15% higher heat losses in the smaller installation, are likely due to a larger ratio between the area for heat loss and the heating capacity,” they pointed out.

Furthermore, due to a different power-to-friction ratio, the larger HTHP B exhibits better volumetric efficiency of 0-3.5% higher, as well as better isentropic efficiency of 6%-8.7%. “At a system level, the smaller setups show better COP at most operating points, due to design effects. If we consider COP as a function of evaporation temperature, efficiencies are on a similar trend line,” she added.

Finally, to further find a general explanation about the scale-up, the scientific group also analyzed the behavior of more than 200 data points of industrial HTHP. They also include an analysis of the systems’ Carnot COP, which is the maximum theoretical efficiency of a heat pump.

“Using these data points, a reasonable assumption for low-fidelity models, for the integration of HTHPs into energy systems or industrial processes, would be to use a COP that is 45% of the Carnot COP for a range operating conditions,” they explained.

Their work was presented in “Experimental research into scale-up effects of high-temperature heat pumps with R1233zd(E)”, published in the International Journal of Refrigeration. The team included scientists from Germany’s University of Bayreuth and the Swiss University of Applied Sciences in Eastern Switzerland.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.