The solar cell was treated with multi-elemental alloy, which reportedly helped eliminate defects in the kesterite absorber, increasing cell efficiency. China’s National Measurement and Test Center for PV Industry confirmed the results.

A group of researchers led by the Chinese Academy of Sciences (CAS) has fabricated a kesterite (CZTSSe) solar cell that achieved a maximum energy conversion efficiency of 14.6% and a certified efficiency of 14.2%.

“The performance of kesterite solar cells is mainly limited by the charge loss caused by defects,” the study’s corresponding author Qingbo Meng said. pv magazine. “We believe that through a more comprehensive understanding of the defect formation mechanism in this material system and more effective control of the defect formation process, we can make greater progress in the future.”

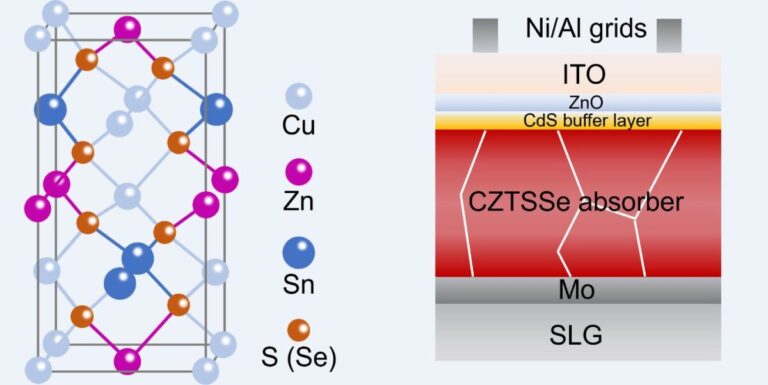

Kesterite is one of the most promising candidates for a light-absorbing material for potential use in lower-cost thin-film solar cells. Kesterites include common elements such as copper, tin, zinc and selenium. Unlike CIGS connections, no supply bottlenecks are expected in the future. However, Kesterite is still less efficient than CIGS in mass production. The world record for such cells is 12.6%, achieved for large-area devices by Japanese thin-film manufacturer Solar Frontier in 2013.

The Chinese research team used what it described as a kinetics-based approach to suppress the formation of deep defects in the CZTSSe absorber. It consisted of using multi-elemental alloy to eliminate tin (Sn) and zinc (Zn) defects in the final CZTSSe material by adding silver (Ag) and cadmium (Cd) via the precursor solution and germanium (Ge) from the rear interface. “Elemental alloying facilitated the exchange of Zn/Sn and Zn/Cu, leading to accelerated formation of the ordered kesterite phase,” the scientists said.

They built the solar cell with a substrate of soda lime glass (SLG) covered with molybdenum (Mo), the CZTSSe absorber, a cadmium sulfide (CdS) buffer layer, a window layer of zinc oxide (ZnO) and indium tin oxide (ITO) layer, and an anti-reflective coating based on magnesium fluoride (MgF2).

The device has been tested under standard lighting conditions achieved an energy conversion efficiency of 14.6%, an open-circuit voltage of 0.55 V, a short-circuit current of 36.6 mAcm−2, and a fill factor of 72.4%. China’s National Measurement and Test Center for the PV Industry stated that the cell achieved an efficiency of 14.2%.

“The main discrepancy between the certified and our laboratory result, that is, the fill factor, is attributed to the influence of the MgF2 anti-reflection layer on the contact with the electrical probe,” the academics explained. “These results indicate that multinary alloy can more effectively regulate reaction kinetics to suppress deep defects in CZTSSe, thus creating more favorable moderate reaction conditions to meet the demands of large-scale and low-cost industrial production.”

The new solar cell concept was introduced in the newspaper “Multinary alloy for facilitated cation exchange and suppressed defect formation in kesterite solar cells with a certified efficiency of more than 14%”, which was recently published in nature energy. “These insights and the data-driven analysis method presented here also provide greater opportunities to identify and regulate defects in photovoltaic materials,” the research team concluded.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.