In a new weekly update for pv magazineOPIS, a Dow Jones company, provides a brief overview of the major price trends in the global PV industry.

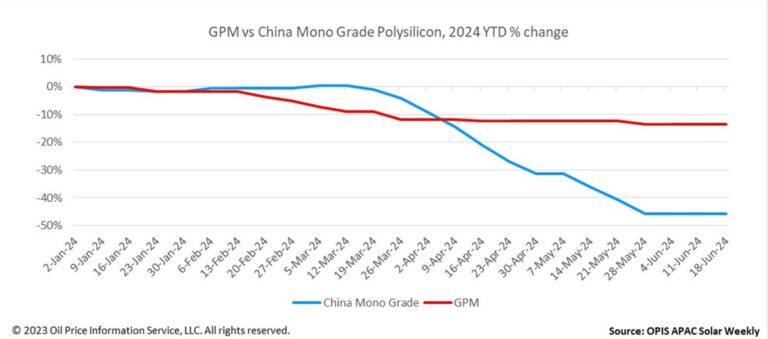

The Global Polysilicon Marker (GPM), the OPIS benchmark for polysilicon outside China, was valued at $22,567/kg this week, unchanged from the previous week, on buy-sell indications. The price has remained stable for four consecutive weeks.

According to a source knowledgeable about the polysilicon market outside China, the trading status of global polysilicon in spot markets is currently largely stagnant, with buyers awaiting the preliminary ruling of the US anti-dumping and countervailing duties investigations expected in July.

A major global buyer of polysilicon reported receiving bargain prices from certain sellers that were lower than the long-term agreement prices for the same specifications. However, due to uncertainty over US trade policy, they have refrained from placing an order.

This information was confirmed by a global polysilicon supplier, who expressed concern: “We are concerned about the accumulation of supplies.”

Nevertheless, there are still optimistic voices in the market, with sources reporting continued positive sales experiences. One of the sources explained that the solar supply chain has three different supply-demand relationships: between polysilicon and wafers, wafers and cells, and cells and modules.

“It is argued that applying the current pessimism of the module market to the global polysilicon market is not justified,” the source added. “Only the relationship between polysilicon and wafers has a direct impact on global polysilicon pricing, which has been proven to be stable without significant fluctuations.”

China Mono Grade, OPIS’ assessment of polysilicon prices in the country, remained stable this week at CNY33 ($4.54)/kg, marking the fourth straight week of stability.

Market participants generally believe that current polysilicon prices do not require any further reduction as this would not significantly boost sales. Wafer companies are constrained by their operating rates and cash flow, limiting their ability to accelerate polysilicon sourcing. “Currently, we are facing a loss of about 0.20 yuan for each piece of waffle produced,” a major waffle producer revealed.

Multiple sources have confirmed that while almost all Chinese polysilicon manufacturers are undergoing equipment maintenance, production cuts or shutdowns, one major manufacturer is operating at full capacity with an operating rate of 100%.

As a result, this company suffers a monthly loss of CNY600-700 million in the polysilicon production segment, the source said, noting that due to the plant’s large production capacity, operating at full capacity will keep the total polysilicon inventory high, bringing uncertainty. on the outlook for polysilicon prices.

Sources indicate that the company’s new production capacity is not only running at full capacity, but is also being ramped up as planned. This strategy underlines the company’s robust cash flow and its intention to leverage economies of scale and cost advantages to undermine the survival space of smaller companies in the ongoing price war.

According to an industry watcher, the current situation of selling polysilicon at significant cash losses is unsustainable. By the end of the year, prices are expected to stabilize slightly above average cash costs in the market, noted the source, who further expects that at that point some of the excess production capacity, especially expensive or outdated facilities, is likely to will be taken away. effectively phased out.

OPIS, a Dow Jones company, provides energy prices, news, data and analysis on gasoline, diesel, jet fuel, LPG/NGL, coal, metals and chemicals, as well as renewable fuels and environmentally friendly feedstocks. It acquired assets with pricing data from Singapore Solar Exchange in 2022 and now publishes the OPIS APAC Solar Weekly Report.

The views and opinions expressed in this article are those of the author and do not necessarily reflect those of the author pv magazine.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.