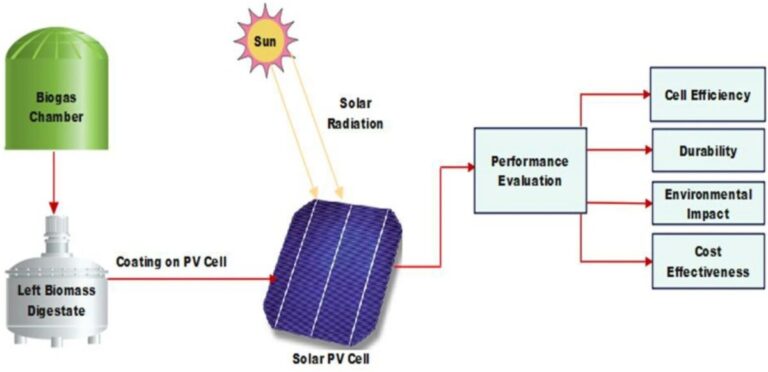

An international research team has proposed using recyclable biomass-digested polymers as materials for PV coatings and encapsulants. The scientists developed a coating for PV cells that reportedly allows for an increase in power of up to 10%.

An international research team has explored the use of recyclable biomass-digested polymers for the production of coatings and encapsulants for PV cells. Digestate polymers are materials released during anaerobic digestion processes that break down organic material in the absence of oxygen. These processes can be used for electricity generation, heating and as a source of biofuels.

“The residual waste resulting from the anaerobic digestion process, known as digestate, poses a significant challenge to the environment if left untreated,” the academics said. “Digestate is a complex mixture of organic and inorganic compounds, including nutrients, heavy metals and pathogens. If released into the environment without proper treatment, it can cause harmful effects, including soil and water pollution.”

In their research, the academic team fabricated cells coated with digestate polymers and examined them for efficiency and durability. They used the EcoPolyBlend (EPB) and the NanoBioCelluSynth (NBCS) digestates.

EPB is a biodegradable polymer blend containing approximately 60% biopolymers, including polysaccharides and proteins. In contrast, NBCS is based on nanomaterials produced by breaking down cellulose-rich anaerobic biomass that is digested into nanoscale cellulose particles. It contains 80% nanocellulose.

“Recovering biodegradable polymers from anaerobic biomass digestate typically involves a series of steps,” the scientists explained. “First, the digestate undergoes a separation process to remove solid impurities and contaminants, leaving a more refined organic residue. This residue, rich in biodegradable materials, is then subjected to various chemical or mechanical treatments to extract and isolate the polymers. These polymers can be further purified and processed into usable forms.”

The researchers conducted 20 experiments for each cell using a solar cell performance analyzer, spectrophotometer, environmental chambers, humidity chambers, stress testers, carbon footprint measuring equipment, soil and water impact analysis tools, and economic modeling software.

“The study includes an extensive experimental design, varying layer thicknesses, direct normal irradiance (DNI), dry bulb temperature (DBT) and relative humidity (RH) to analyze how different types of recovered biodegradable polymers interact with various environmental conditions,” the group explained.

The analysis showed that the EPB allows for a 2% increase in power, while the NBCS provides a 10% increase. However, the EPB offers a five-year lifespan compared to the three years of the NBCS. The former requires a 150nm coating, while the latter requires a thicker 200nm layer. The EPB is also 20% cheaper than the NBCS.

“The ability of the EPB to maintain 95% of initial efficiency after ten years of exposure is commendable,” the researchers added. “The NBCS excels in high humidity conditions, extending the life of solar cells by eight years compared to uncoated cells. Optimization showed that better results were achieved at DNI=8 W/m2, DBT=40 C and RH=70% for both coated materials examined.”

Their findings were presented in “Sustainable coatings for green photovoltaic solar cells: performance and environmental impact of recyclable biomass digestate polymers,” published in Scientific reports. The group included researchers from Saudi Arabia’s Qassim University, India’s Jamia Millia Islamia, Al Falah University, Raj Kumar Goel Institute of Technology and Ethiopia’s Mizan-Tepi University.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.