Researchers at the University of California, San Diego (UCSD) have developed a new silver-free adhesive for shingled solar cells. The new adhesive is based on the PEDOT:PSS polymer and can reportedly reduce silver consumption to approximately 6.3 mg/W.

A group of scientists from the University of California, San Diego (UCSD) have shown that conjugated polymers, a class of electronically conductive plastic materials, can be used as an intrinsically conductive adhesive (ICA) to bond solar cells together.

“This is a new application for a unique class of plastic materials that we are very excited about,” said the study’s corresponding author, Alexander Chen. pv magazine. “Although this research is still in its infancy, an exciting aspect of this work is the depth of literature and the diverse chemistry that can be integrated into conjugated polymers for the purpose of creating new types of conductive compounds and adhesives.”

Shingle solar panels have a rail-free structure where only a small portion of the cells are not exposed to sunlight. The cells are bonded with electrically conductive adhesive to form a high-density shingle array and the resulting strips are bonded together. The reduced number of rails reduces shadow losses.

The shingled cells used in the experiment were built with cell technology from California-based startup Sunpreme and intrinsically conductive adhesives (ICAs) based on the PEDOT:PSS polymer. The performance of solar cells built with ICAs was compared with that of counterparts based on silver-based electrically conductive adhesives (ECAs) and the scientists found that the former exhibited “similar” electrical properties.

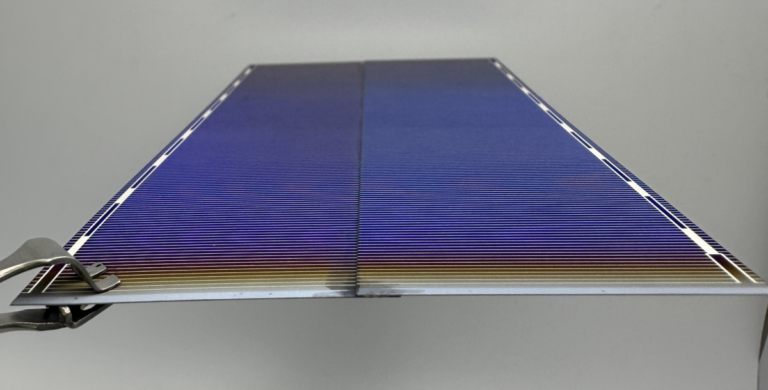

Image: University of California, San Diego

“While the current dominant busbar-based modules require approximately 15.8 mg/W of silver, we calculate that shingling modules with ICAs can reduce silver consumption to approximately 6.3 mg/W, increasing our position on the silver learning curve with can be accelerated by about twenty years. These findings suggest that the design of pi-conjugated materials for ICAs could provide a realistic strategy for the sustainable deployment of lower-cost, high-performance solar modules,” the paper said.

Even with the removal of silver filler, the researchers achieved similar fill factors (FFs) and overall energy conversion efficiency with shingled connections. “Additionally, using a conductive polymer like the ICA opens up a wide range of possibilities for tuning the electronic, mechanical and adhesive properties for designing next-generation electronic interconnects,” she added.

Improvements are possible to further apply the research, as the researchers acknowledged in a statement pv magazine. However, they are optimistic that these can be achieved.

“Although we found that adhesion must be improved to reach that of commercial products, we are optimistic that designing better conjugated polymers for applications such as intrinsically conductive adhesives can be achieved relatively quickly,” Chen emphasized. “This area of research builds on the incredible wealth of knowledge that already exists on tailoring the electrical properties of conductive polymers and the adhesive properties of traditional polymers. There is a large synthetic space that can be quickly explored here.”

The researchers said they had collaborated with a PV engineering company – D2Solar, Inc. – to integrate the proof-of-concept shingles. “We look forward to working with PV manufacturers to test the concept on a larger scale and in relevant outdoor environments,” she added.

The ICAs were presented in the paper “Silver-free intrinsically conductive adhesives for solar cells with shingles,” published in Cell reports natural sciences.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.