Sticky Solar Power is taking orders for industrial-scale versions of its new room temperature cell interconnection system, which is said to be well suited for back-contact (xBC), perovskite and heterojunction cell technologies.

Swedish stringer manufacturer Sticky Solar Power has announced that it is taking orders for its industrial room temperature cell interconnection system based on its tape solution, instead of soldering. A maximum of 20 rails can be used simultaneously and the throughput speed varies from 2,500 to 3,500 single-track connections per hour.

The solar stringer supports lead-free interconnection and uses 60% less silver than conventional processes, said co-founder and CEO Jonas Buddgård. “It can be integrated into any production line because it is made for batch or in-line production with a small factory area of only 6 m²,” Buddgård said. pv magazine. “Equipped with an optional layout, the size increases to approximately 10 m² depending on output preferences.”

The initial target groups are European and American manufacturers of back-contact (xBC), perovskite, heterojunction and bifacial products.

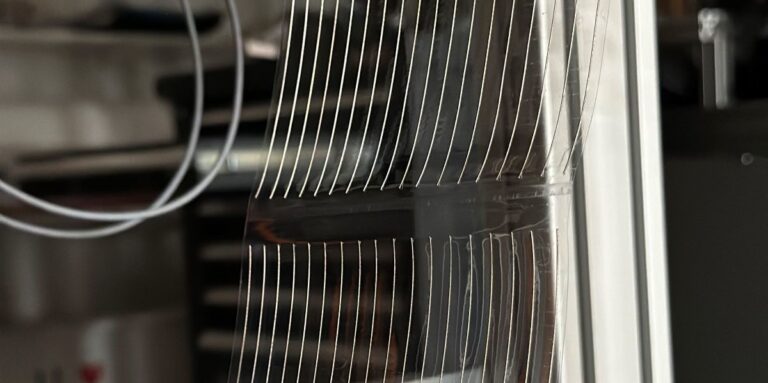

The Sticky Solar Power stringer is based on a tape solution, i.e. the connecting wires are attached to an adhesive tape which in turn is precisely applied to cell surfaces by the equipment. The tape holds the wires and cells in place until the encapsulant laminating step. The tool eliminates single-cell soldering and effectively combines interconnection and laminating steps in one.

“Because the stretching is carried out at room temperature, the maximum required process temperature for the tape solution is only 150°C,” says Buddgård, noting that the equipment can be used up to 24 hours a day, 365 days a year. It works with both ethylene vinyl acetate (EVA) copolymer and polyolefin elastomer (POE) materials.

“We have made it competitively priced, comparable to other European manufacturers. The capital expenditure, perceived risk and operational expenditure are competitive, that is the whole idea of the tape solution,” says Buddgård.

While well suited for cell processing at lower temperatures as an alternative to conventional soldering, the equipment also offers benefits to manufacturers of monocrystalline passivated emitter rear cells (PERC) and tunnel oxide passivated contact (TOPCon), such as reduced number of steps and less material consumption, according to Company.

Lower temperatures also mean a lower risk of solar cells bursting. It can also reduce warping or bending of solar cells with back contact.

The supported cell technologies include heterojunction, perovskite, perovskite-silicon tandem, PERC and TOPCon, bifacial and xBC designs. It supports standard sizes, such as M2, M6, M10 and M12. The tape has been used in back contact mini modules that have passed the thermal cycling tests of IEC 61215.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.