A research team consisting of scientists from Italian module manufacturer 3Sun has tested new zirconium-doped indium oxide electrodes in commercial heterojunction solar panels. The new electrodes are said to achieve the same performance as their indium tin oxide-based counterparts and pave the way for lower indium consumption in heterojunction products.

A European research group led by Italy’s University of Catania has tested the use of zirconium (Zr) doped indium oxide (In2O3) as a transparent conductive film in the silicon heterojunction (HJT) solar cells developed by module manufacturer 3Sun, a division of the Italian manufacturer . energy company Enel.

“Reducing the use of indium can be achieved by reducing the thickness of the films of transparent conductive oxides (TCOs),” the researchers explain. “The main issue for a reduced thickness TCO is related to the resulting increase in plate resistance. So the key point is the doping of indium oxide with impurities that can improve conductivity.”

The scientists tested the film in different configurations, with varying Zr atomic concentrations and thicknesses. They decided to dope the In2O3 with Zr because it is a type III transition metal (TM) that can be realized with high carrier mobility and concentration.

All films in this experiment were deposited at room temperature and underwent thermal post-deposition treatment at 200 C in air. “That makes the synthesis procedure compatible with industrial manufacturing processes and applications in flexible devices with polymer substrates,” they emphasized.

Zirconium-doped indium oxide (IZrO) thin films were deposited in an area of 4 cm × 4 cm. While the standard value of the thin film in commercial crystalline silicon solar cells is usually 100 nm, the IZrO in the first experiment was 40 nm thick. At the same time, the Zr content varied from 0.6 at.% to 0.9 at.%.

With a Zr atomic concentration of 0.6%, films with different thicknesses of 15 nm, 40 nm and 90 nm were prepared. “The thinnest film of 15 nm was compared with other ultrathin TCO films (ITO-20 nm and AZO-20 nm) that showed the lowest sheet resistance,” the academics said.

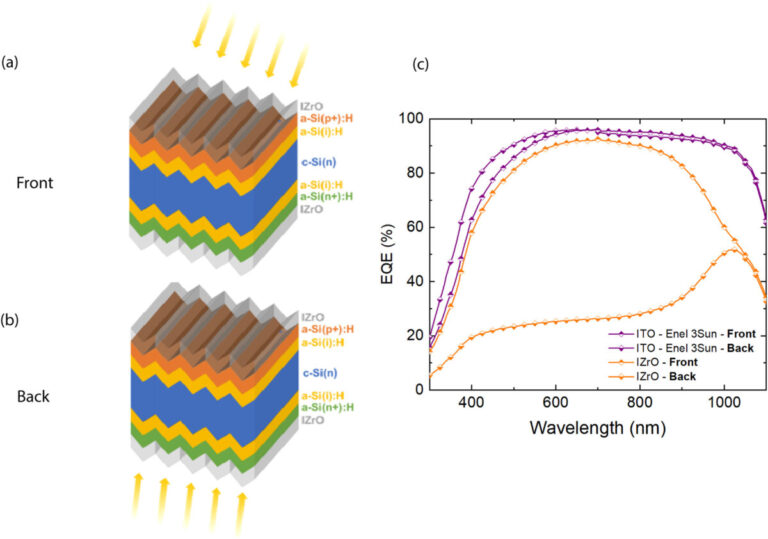

Finally, the group tested the IZrO electrodes on solar cells. They used 90 nm IZrO films as both front and back contacts of the bifacial silicon HJT devices. The performance of IZrO electrodes was found to be “comparable” to that of standard indium tin oxide-based counterparts.

“These results suggest that ultrathin IZrO films can be successfully used to reduce the cost and amount of indium used in indium-based transparent conductive oxide layers for solar cells,” the research group said.

The new films were presented in the study “Zirconium-doped indium oxide thin films as transparent electrodes for photovoltaic applications,” published in Solar energy materials and solar cells. The research was conducted by scientists from the Italian University of Catania, the National Research Council, Enel Green Power, the Dutch institute AMOLF Physics of Functional Matter and the University of Amsterdam.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.