A Chinese research team modified the absorber of a conventional perovskite solar cell with potassium trifluoromethanesulfonate (KTFS) and found that the additive improved the device’s performance and stability. The cell perovskite film reportedly showed fewer lead defects and lower JV hysteresis.

Researchers from Hangzhou Dianzi University in China have fabricated a perovskite solar cell using a multifunctional additive known as potassium trifluoromethanesulfonate (KTFS), which they claim can significantly reduce lead vacancy in the perovskite film.

“The KTFS molecule is a typical type of potassium salt, including the cationic potassium (K+) and anionic trifluoromethanesulfonate (SO3C.F3−), indicating a bifunctional interaction between KTFS and perovskite,” they explained. “The sulfonyl group can passiveize the undercoordinated conduit of the deep-level defect and thus inhibit non-radiative recombination.”

In the study “Modulating vacancy-related defects and hole extraction via a multifunctional additive for high-performance perovskite solar cells,” published in Cell reports Natural Sciences, The research group described the results of the proposed potassium-based salt additive as better surface morphology and higher crystallinity in a film built with a lead iodide (PbI2) layer treated with KTFS via thermal annealing.

The performance of the KTFS-modified film was compared to that of a control perovskite film without the additive, and the former was found to have fewer lead impurities than the control film. “The presence of Pb impurities in perovskite films is the result of the dissolution of residual PbI2 when exposed to light or X-rays, indicating an iodine deficiency in the films,” the academics said. “These metal lead clusters act as impurities, which can accelerate the degradation of perovskite films and affect the stability of perovskite solar cells.”

Furthermore, KTFS was found not to affect the 1.52 eV energy bandgap of the formamidinium lead iodide (FAPbI).3) perovskite material selected for the film.

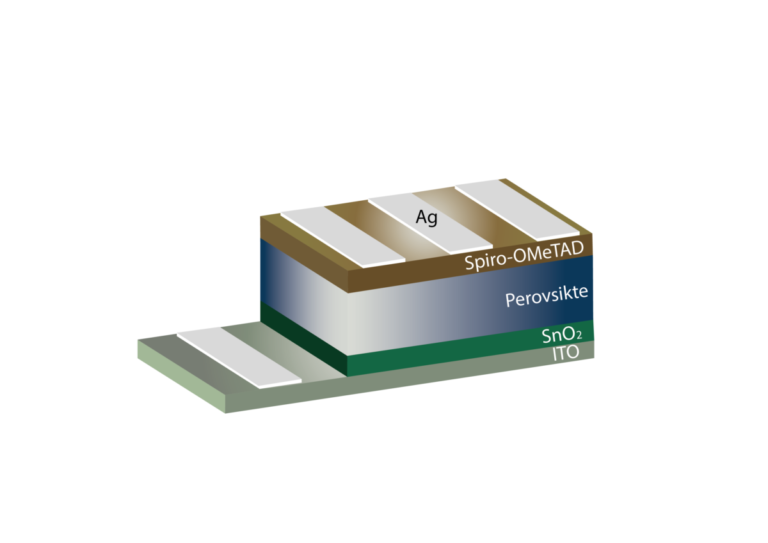

The group built the solar cell with a substrate made of indium tin oxide (ITO), an electron transport layer (ETL) based on tin oxide (SnO2), the KTFS-modified perovskite absorber, a hole transport layer (HTL) relying on Spiro-OMeTAD and a silver (Ag) metal contact.

Tested under standard lighting conditions, the device achieved an energy conversion efficiency of 23.96%, an open-circuit voltage of 1.165 V and a short-circuit current density of 25.29 mA/cm2and a fill factor of 81.33%. For comparison: a reference device without KTFS achieved an efficiency of 22.23%, an open-circuit voltage of 1.15 V, a short-circuit current density of 25.03 mA/cm2and a fill factor of 77.24%.

“The KTFS-adapted device shows a relatively low hysteresis index with a value of 4% compared to 6.8% for the control device,” the scientists said. “It is speculated that the existence of K+ incorporated into KTFS with perovskite can inhibit and therefore reduce ion migration JV hysteresis.”

The group also found that the KTFS-modified cell was able to maintain 90% of its original efficiency after 1,200 hours of storage, while the control device achieved only 80%.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.