Researchers from the US and South Korea have developed a method to make high-quality perovskite films at room temperature. The film was tested in a conventional perovskite solar cell architecture and the result was an energy conversion efficiency of more than 24%.

An international research team has developed a method to make high-quality perovskite films at room temperature for applications in perovskite solar cells. The new process avoids thermal annealing and additional post-treatments.

The team selected a perovskite compound known as (CsX(FA0.92MA0.08)1−xPb(i0.92Br0.08)3), which was converted to a-FAPbI3 at room temperature. Further conversion was promoted by the addition of an organic linker known as oleylamine or simply OAm. The effect of the method on quality growth patterns was confirmed by in situ X-ray monitoring.

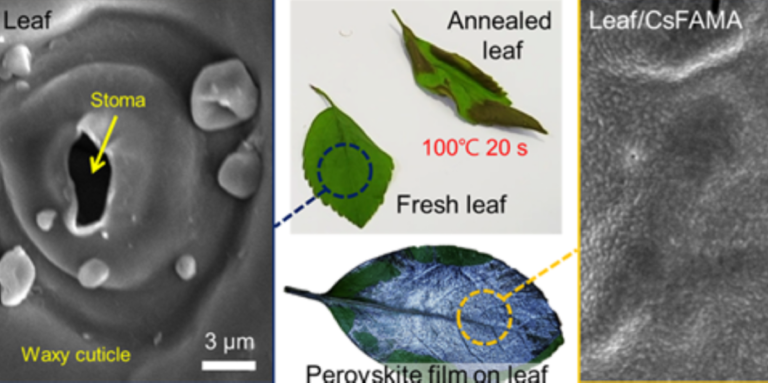

Additionally, to demonstrate the feasibility of the process on non-traditional PV substrates and materials, the researchers deposited their perovskite film on a plant leaf, something that would have been impossible with conventional methods.

“The most challenging aspects of the work were understanding the mechanism of action and then demonstrating that the process was gentle enough to deposit perovskite films on fresh leaves, which are very soft and fragile,” says lead study author Thuc-Quyen Nguyen . pv magazine.

The researchers described the fabrication of cells with a planar pin structure to investigate the effect of cesium (Cs) and OAm on performance and said they used only printable materials. The fabricated devices had an indium tin oxide substrate with a spin-coated layer of MeO-2PACz, also known as [2-(3,6-Dimethoxy-9H-carbazol-9-yl)ethyl]phosphonic acid.

The perovskite absorber then underwent a two-step spin-coating process and was connected to an electron transport layer (ETL) based on phenyl-C61-butyric acid methyl ester (PCBM) that also relied on spin-coating and a bathocuproin (BCP). buffer layer. All of the foregoing was achieved without thermal annealing. Finally, a 100 nm thick silver metal contact was thermally deposited on the substrates as cathodes in a thermal vacuum evaporator.

Reproducibility was assessed over 100 devices with varying amounts of experimental materials. Observing the results, the team noted that the addition of OAm “significantly softened” the deviations and improved the device properties, and that the Cs10+OAm devices showed the highest short-circuit current density, open-circuit voltage, and fill factor with the smallest deviations. of efficiency.

The team said that the optimized Cs10+OAm device achieved “impressive efficiency” of 23.2%. With an anti-reflective coating this was increased to 24.4%. It noted that the results exceeded the efficiencies achieved with previous low-temperature and room temperature (RT) processed perovskite solar cells (PSCs).

“Through a combination of characterization techniques, we revealed the morphology and device physics of RT-processed PSCs. Finally, we demonstrated that annealing-free processing enables the fabrication of high-quality perovskite films on sheet substrates,” the researchers concluded.

The details of the study appear in “Room temperature processed perovskite solar cells with an efficiency of more than 24%,” published in Joule. The researchers came from three institutions: the University of California, Santa Barbara, Korea’s Pusan National University and the Korea Electric Power Research Institute.

Looking ahead, the teams plan to work on integrated PV and indoor PV technologies. “We are currently focusing on developing efficient semi-transparent solar cells that achieve an efficiency of more than 12% while guaranteeing a transparency level of more than 30%. These cells are designed for integration into building windows, vehicles and greenhouses,” said Nguyen.

“In addition, we are actively involved in the development of indoor solar cells that can achieve an efficiency of more than 40% under LED lighting conditions. This breakthrough has the potential to provide renewable energy to power indoor appliances and systems.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.