Scientists in South Africa have proposed a new design of a chalcogenide perovskite solar cell based on a compound known as barium zirconium sulfide. They tested different hole transport materials in the new device and found that a polymer known as P3HT provided the best performance.

A team of scientists led by the University of Fort Hare in South Africa has designed a perovskite solar cell with an absorber made from a chalcogenide perovskite material known as barium zirconium sulfide (BaZrS3).

Metal chalcogenide perovskites, with their non-toxic elemental composition, are known to provide greater thermal and aqueous stability than organic-inorganic halide perovskites. This means that they may be more suitable than other materials in the perovskite family to address the two biggest problems in commercial solar cell production: low thermal stability and toxicity. Furthermore, chalcogenide possesses an optimal band gap of 1.40 eV, which is particularly suitable for single-junction photovoltaic applications.

BaZrS3 is a non-toxic, abundant, inorganic chalcogenide perovskite material that has attracted the attention of the scientific PV community in recent years because it crystallizes in a perovskite structure, while also exhibiting very strong light absorption and good charge transport. Moreover, it contains naturally occurring and non-hazardous components with remarkable crustal concentration.

In the newspaper “A numerical simulation and analysis of chalcogenide BaZrS3-based perovskite solar cells using different hole transport materials,” published in Results in physicsthe research team explained that it was using the SCAPS-1D solar cell capacity software, developed by Ghent University, to simulate the new cell configuration.

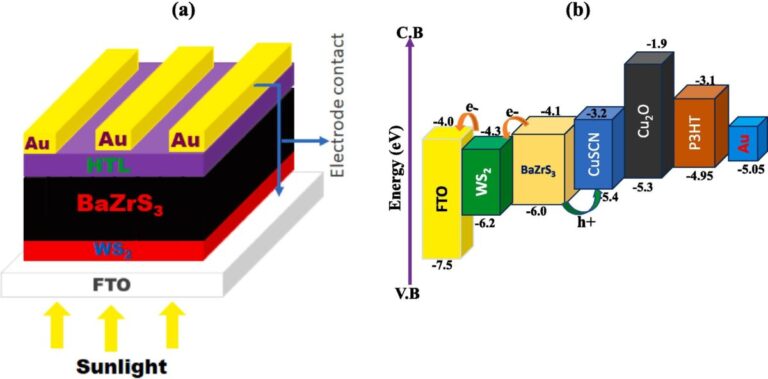

The cell is designed to be made from a substrate tin oxide (FTO), an electron transport layer dependent on tungsten disulfide (WS2)the BaZrS3 absorber and a gold (Au) metal contact. Various materials have been tested for the hole transport material (HTL), namely polymer Regioregular poly(3-hexylthiophene) (P3HT)copper(I) oxide (Cu2O), and copper thiocyanate (CuSCN).

Through a series of simulations performed under standard lighting conditions, the researchers found that the best performance was achieved by the cell with the P3HT HTL. It achieved a current conversion efficiency of 13.86%, an open-circuit voltage of 6.58 V, a short-circuit current density of 17.59 mA cm3−2and a fill factor of 11.97%. For comparison: the Cu2O-cell and the CuSCN device achieved efficiencies of 13.70% and 13.80%, respectively.

“On the other hand, the devices with inorganic HTL (CuSCN and Cu2O) were more thermally stable (stable up to 400 K) than the devices with P3HT as HTL, which were only stable up to 320 K,” the scientists further explained. “Finally, relatively cheaper metals such as (platinum) Pt, nickel (Ni) and palladium (Pd) showed similar performance in all modeled solar cells as gold and can thus be used as potential alternatives.”

The group also found that a reference cell using an HTL made of Spiro-OMeTAD achieved an energy conversion efficiency of 16.70%, an open-circuit voltage of 1.08 V and a short-circuit current density of 16.80 mA cm3.−2and a fill factor of 88.60%.

“It is expected that this work will shed additional light on the use of BaZrS3 as a promising absorber material in the actual production of solar cells for clean energy production,” the academics concluded.

The first attempt to develop BaZrS3 for PV applications dates back to 2020, when a US research team developed a thin film that was examined to determine its optical and electrical properties.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.