US scientists have developed a thermofovoltaic cell that can be combined with cheap thermal storage to provide power on demand. The indium gallium arsenide (InGaAs) thermofovoltaic cell absorbs most of the in-band radiation to generate electricity, while serving as a near-perfect mirror.

Thermophotovoltaic energy (TPV) is a power generation technology that uses thermal radiation to generate electricity in photovoltaic cells. A TPV system typically consists of a thermal emitter that can reach high temperatures, close to or above 1000 C, and a photovoltaic diode cell that can absorb photons coming from the heat source.

The technology has attracted the attention of scientists for decades because it is possible captures sunlight across the entire solar spectrum and has the technical potential to beat the Shockley-Queisser limit of traditional solar photovoltaics. However, the efficiencies reported so far are too low to make it commercially viable as TPV devices still suffer from optical and thermal losses.

With this in mind, a group of researchers from the University of Michigan in the United States has developed TPV cells reportedly address these issues and achieve an energy conversion efficiency of 44%.

“This level of efficiency could allow thermal battery systems to reach a price point needed to power most of the grid on wind and solar energy,” said Andrej Lenert, the study’s lead author. pv magazine. “Such systems must continuously extract energy from a hot storage material such as graphite as it cools from the maximum allowable temperature. By achieving 40% efficiency at storage temperatures as low as 1300C, instead of 2000C as before, this means these batteries can potentially get twice as much energy per kg of graphite.”

According to Lenert, this result represents a major improvement in TPVs and solid-state heat generation in general. “It is the result of several years of intensive research to understand how to minimize energy losses and mechanical issues in airlift TPV cells, which we originally reported in 2020,” he added. “Those cells were 32% efficient and relatively vulnerable, now we are closer to 44% and we have a much more robust technology. While still not on the kW or MW scale, this result shows what is possible with single-junction TPV cells, fulfilling decades-old theoretical predictions from the TPV community.”

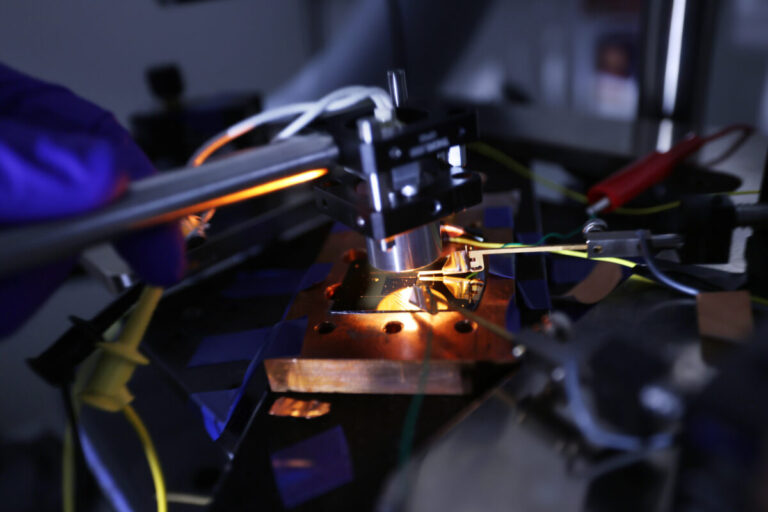

In the study “High-efficiency thermophotovoltaic cells with air bridge”, which was recently published in JouleLenert and his colleagues described the cell as an airlift device of indium gallium arsenide (InGaAs) that can absorb most of the in-band radiation to generate electricity. It can also serve as a near-perfect mirror, with a reflectivity of almost 99%.

The cell is built with a silicon substrate, an airlift structure with a thickness of 570 nm, a back contact made of gold (Au), titanium (Ti), an n-doped InGaAs layer, a membrane layer with a thickness of 1 µm, an InGaAs absorber and a front contact made of Au, Ti, platinum (Pt) and p-doped InGaAs. Three different absorber layers were tested with energy band gaps of 0.74 eV, 0.90 eV and 1.1 eV, respectively.

The The airlift layer is embedded between the three active layers and the back Au mirror to enhance back reflection and out-of-band photon recovery. The membrane support layer is intended to minimize buckling of the free-standing semiconductor membrane and ensure a single cavity mode within the air layer.

“The combination of a nanoscale air layer and a relatively high coverage of conductive back electrodes ensures that the thermal resistance of the air bridge is small compared to that of the Si substrate,” the scientists pointed out. “In addition, the design includes a membrane support layer to minimize buckling of the free-standing semiconductor membrane and ensure a single cavity mode within the air layer.”

The researchers found that the cell had an absorber band gap of 0.90 eV achieved the best performance. It achieved an energy conversion efficiency of 43.8% at 1,435 C. “It exceeds the 37% achieved by previous designs within this temperature range,” Lenert said. “We have not yet reached the efficiency limit of this technology. I am confident that in the not too distant future we will get above 44% and push 50%,” said study co-author Stephen R. Forrest.

These results also promise significant improvements in the return efficiency of the device, according to the research group. “It is a form of battery, but one that is very passive. You don’t have to extract lithium like you do with electrochemical cells, which means you don’t have to compete with the electric vehicle market,” Forrest further explains. “Unlike pumped water for hydroelectric energy storage, you can put it anywhere and you don’t need a water source nearby.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editorial@pv-magazine.com.