Scientists in China have prototyped a PV system that integrates phase change materials, a thermoelectric generator and thermal collectors. The three technologies are intended to cool the solar panel and increase the efficiency of energy generation.

Scientists from Tianjin Chengjian University in China have fabricated an experimental photovoltaic device that integrates three different technologies aimed at improving performance: a phase change material (PCM), a thermoelectric (TEG) generator and thermal collector (T) devices .

PCMs can do that absorb, store and release large amounts of latent heat within defined temperature ranges. They are often used at research level for the cooling of PV modules and the storage of heat.

TEGs can convert heat into electricity through the ‘Seebeck effect’, which occurs when a temperature difference between two different semiconductors causes a voltage between the two substances. The devices are often used for industrial applications to convert excess heat into electricity. However, its high cost and limited performance have so far limited its wider application.

“The system has good economic potential due to its excellent temperature control, high power generation and energy efficiency, and is expected to be more widely used in the future as the cost of thermoelectric chips decreases,” said the study’s lead author, We Li. told pv magazine.

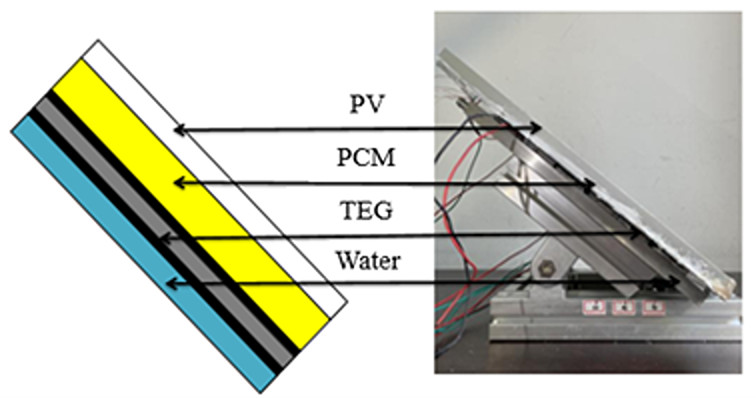

The system uses PCM, TEG and cooling water to absorb excess heat from the PV panels, effectively controlling the temperature of the PV panels and extending their lifespan. At the same time, the PCM provides a stable heat source for the TEG and the water cooling panels provide a cold source for the TEG. The TEG generates electricity from the temperature difference between the two sides of the hot and cold sources, improving the overall power generation rate of the PV system. The cooling water recovers the remaining heat to improve the use of solar energy.

The PV-PCM-TEG-T was constructed by placing an aluminum frame on the back of the PV panel to form a cavity in which PCM could be embedded and sealed with an aluminum sheet. The series-connected TEGs were attached to the back of the aluminum plate with thermally conductive silicone. Furthermore, a water cooling plate was used on the other side of the TEGs.

Image: Tianjin Chengjian University

The academics built an experimental prototype of the PV-PCM-TEG-T system and compared its performance with that of a reference PV panel without the PCM-TEG-T structure.

“In numerical simulations, the heat transfer of the PV-PCM-TEG-T system was numerically modeled,” Li explains. “Under 24-hour operating conditions, the PV-PCM-TEG-T system exhibits higher temperature control compared to standard PV panels.”

The proposed system was found to have 10.4% higher output power and 1.9% higher energy generation efficiency than the reference system. “Under the 24-hour simulation condition, the temperature of the new system is significantly lower than that of the standard PV panel, with a maximum temperature difference of 10.1 C,” the research group further explained. “PCM thickness has little impact on the ability to regulate temperature, while increased PCM thickness increases heat storage, thereby increasing TE power generation.”

“Comparing with standard PV panels under 3 hours of radiation and 3 hours of non-radiation, the system can effectively control the temperature of the PV panels and improve the energy generation efficiency,” Li added. “The addition of TEG increases energy generation capacity; the circulating cooling water improves the temperature difference, increases the thermoelectric energy generation capacity and realizes heat recovery and storage.”

The researchers presented the system in the study “Experimental and numerical investigation of photovoltaic thermoelectric heat storage systems based on phase change temperature control,” published in Solar energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.