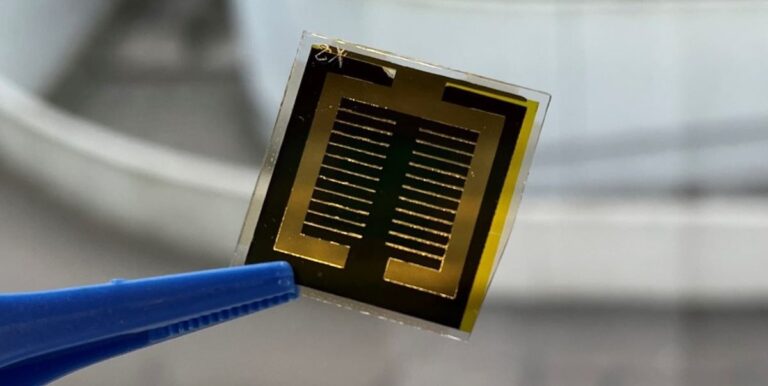

Researchers at the Karlsruhe Institute of Technology (KIT) have developed a scalable two-step evaporation and inkjet process for perovskite thin-film solar cells. The new technique reportedly makes it possible to build champion cells with the same efficiency as those made with the spin coating process.

A research team from the Karlsruhe Institute of Technology (KIT) has developed a scalable two-step process for the formation of organic perovskite thin films that has the potential to be used on structured substrates.

The process, described as a scalable and reliable technique for high-performance perovskite deposition, combines the use of an evaporated lead iodide layer with inkjet-printed organic perovskite precursor materials.

“It was a challenge and a great success to bring the performance of vaporized lead iodide solar cells to the same performance level as devices with a spin-coated lead iodide scaffold,” said corresponding lead author Raphael Pesch. pv magazine, adding that the team was able to adjust the porosity with a low-cost vapor treatment with dimethyl sulfoxide (DMSO). “We identified early on that the porosity of the lead iodide in the first step is critical to the conversion in our two-step manufacturing process.”

The process is also said to exhibit high reproducibility and potential for conformal growth on textured silicon, and to yield films free from drying effects and toxic solvents.

With the proposed technique, the films are applied using a Pixdro LP50 inkjet printer from the German supplier SÜSS, equipped with a Sapphire QS-256/10 AAA print head, which has 16 times more nozzles than typical print heads used in laboratories for this type applications are used. application. “This not only helps increase the interaction time between the droplet and the surface, which is necessary to avoid drying effects on large surfaces, but also reduces the chance of pinholes,” says Pesch.

Referring to the sapphire print head used in the study, KIT’s next-generation PV group leader Ulrich W. Paetzold pointed out that it could also be used in larger printers, such as Notion Systems’ n.jet lab, which covers areas can print 0.61 x 0.61 square meters at a speed of 2 meters per second.

Paetzold underlined the cost-effectiveness of the process. “The organic precursor materials required for the construction of perovskite solar cells can be quite expensive,” he added. “Although material yield upon evaporation is typically low, inkjet printing allows us to achieve a near-perfect material yield of almost 100%.”

By optimizing printing parameters, the group has achieved championship devices with an efficiency of 18.2%, which it says is “on par with their spin-coated counterparts.”

“We were very surprised in the laboratory to see the significant impact this additional step has on the performance of the cells,” Paetzold said. pv magazinenoting that there is still some work to be done to outperform the laboratory-based spin coating process.

“The spin-coated reference devices still perform slightly better compared to the scalable processes,” Paetzold said. The optimal results in this study were attributed to the morphology of the lead iodide thin film and the selected resolution of the printing process, as well as to the mixing and stoichiometry step enabled by the DMSO vapor treatment to increase the porosity of lead iodide.

The new technique was described in the article “Hybrid two-step inkjet printed perovskite solar cells”, which was recently published in RRL solar energy.

Looking ahead, the team will work to integrate the process into the manufacturing of tandem and large area devices. “The ultimate goal is to process full-size wafer silicon bottom cells,” says Paetzold.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.