A group of Chinese researchers have made an initial attempt to integrate pumped hydropower plants with compressed air storage and have found that the latter can help the former better cope with large head variations.

Researchers from China’s Harbin Institute of Technology proposed combining pumped hydropower storage systems with compressed air energy storage (CAES) technology in an attempt to address a well-known problem of pumped hydropower systems – dealing with large head variations in hydraulic machines.

“We designed a novel compressed air pumped hydro energy storage system, which integrates pumped hydro storage, compressed air energy storage and hydraulic potential energy transfer technologies,” said the study’s corresponding author Deyou Li. pv magazine. “We also analyzed the composition and operating principle of the system, as well as the thermodynamic model of each module. Its accuracy was verified by comparing our results with existing literature data.”

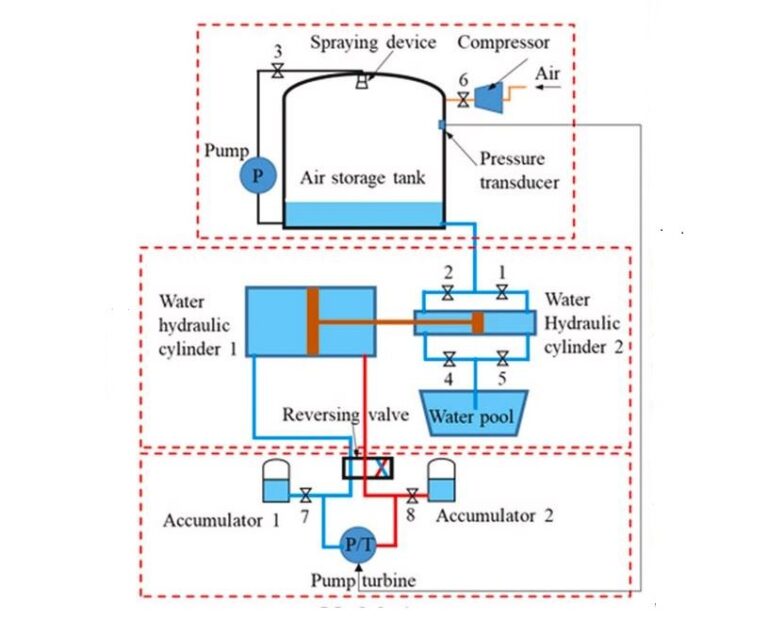

In the newspaper “Energy and exergy analysis of a new energy storage system with pumped hydro-compressed air,” published in Energy, the research group explained that the system works through multiple charging and discharging processes. It consists of a pump storage, a reversing valve, a spray device, water hydraulic cylinders, an air storage tank, a pump, a water basin and various valves.

In the charging phase, the system extracts water from the water pond via hydraulic machines. The water is then pushed into the air storage container for air compression. During unloading, the air in the air storage container expands and the water

that comes out of the container is injected into the hydraulic machines to generate electricity.

“The proposed system can store and release energy through charging and discharging, allowing it to perform peak-shaving and valley-filling functions,” the academics said. “When the electrical load is small, the excess electrical energy is absorbed by the pump storage unit and converted into internal energy of the compressed air for storage. Conversely, the system supplies power to the grid.”

The system also uses a spray device to improve heat transfer between the air and water in the tank, achieving near isothermal compression and expansion.

“When the sprayer is not in use, the air temperature rises to 36 C during charging and drops to 6.4 C during discharging,” the group explains. “During spraying, the variation in air temperature under charge, standby and discharge conditions decreases significantly. The maximum value of air temperature during charging decreases to 28.4 C and the minimum value of air temperature during discharging increases to 13.2 C.”

The scientists tested the proposed system configuration through a series of simulations and assumed that the system would have a capacity of 1 MW. They calculated a charging time of 31.1 minutes and a discharging time of 23.1 minutes.

The analysis showed that the water pressure potential energy transfer module adopted in the system can effectively convert the pressure variation of nearly 1.6 MPa in the air storage tank to a head variation of 58.5 m during pumping and 48.2 m during power generation of the pump storage. It also showed that pumped storage has the highest energy waste and is the part of the system that needs further optimization within an overall approach aimed at reducing system complexity.

“In future studies, the number of energy transformations in the proposed system will be further reduced,” the researchers concluded. “An experimental platform will then be developed to verify the technical feasibility of the proposed system and reveal the effects of key design parameters, such as initial pressure, final pressure, air storage tank volume and variable pressure ratio, on air storage. operational performance of the system.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.