The device was invented by scientists in China and consists of a Fresnel lens, a PV cell and liquid ionic thermocells (iTECs) with electrolyte flow. Reportedly, CPV systems built with thermoelectric generators can perform better in both cost and efficiency.

A group of scientists from North China Electric Power University have developed a hybrid energy system that combines concentrated solar photovoltaics (CVP) and liquid ionic thermocells (iTECs).

“The application of ionic thermocells in the full spectrum of solar cascade use of concentrated photovoltaic systems has proven feasible with significant advantages of low cost, high performance and flexible operation,” said the study’s lead author, Zhuo Liu. pv magazine, noting that iTECs were used as an alternative to commonly used thermoelectric generators (TEGs). “During the comparison, it is clear that the iTEC with the dual capabilities of heat-to-electricity conversion and PV cooling can greatly simplify the overall structure of the hybrid system and save costs from the expensive TEG, which is promising for practical application, to eliminate. ”

TEGs can convert heat into electricity through the ‘Seebeck effect’, which occurs when a temperature difference between two different semiconductors causes a voltage difference between two substances. The devices are often used for industrial applications to convert excess heat into electricity. However, its high cost and limited performance have thus far limited its wider adoption.

iTECs can also convert low-grade heat into electricity and are cheaper than TEGs, according to the researchers. They also have an ionic Seebeck coefficient high enough to ensure efficient harvesting of waste heat and cooling from PV in CPV systems. “Although the thermoelectric properties of iTEC may decrease due to the lower temperature difference as heat transfer increases, the overall electrical and thermal performance of the CPV-iTEC hybrid system would be improved due to the higher power of PV at lower temperatures,” explained them out. .

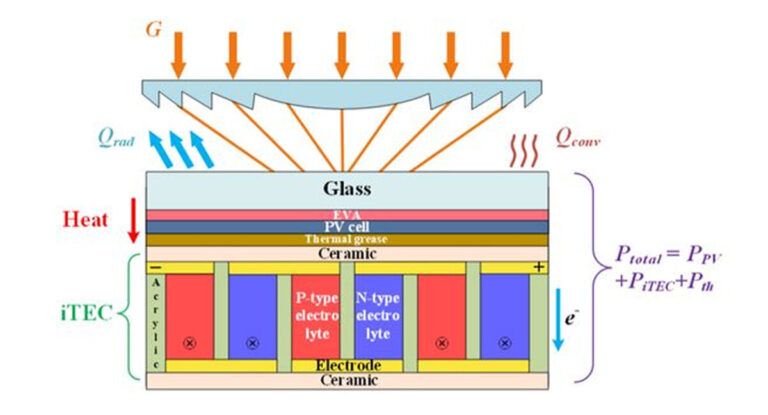

The CPV-iTEC hybrid system consists of a Fresnel lens, a photovoltaic cell and an iTEC with electrolyte flow. It uses the waste heat generated by the PV unit to produce additional power via the thermogalvanic effect of iTECs, which in turn increases the output of the overall system. The iTEC is attached to the back of the PV cell using thermal grease with high thermal conductivity

“The total power of the CPV-iTEC hybrid system is mainly composed of the electrical power of PV and iTEC, and the thermal power of flowing electrolytes in iTEC,” the academics pointed out. “The output power of iTEC depends on the channel structure and the properties of the electrolytes/electrodes.”

The group compared the hybrid system’s performance to a reference system that used a TEG generator instead of iTECs. The latter used a water cooling body that was attached to the back via thermal grease to cool the PV cell.

During experimental and numerical analyses, the scientists found that the presence of iTEC can significantly reduce the temperature of photovoltaic panels from 351.30 K to 325.14 K, thus broadening the available concentration ratio from 1~21 to 1~39 compared to typical CPV-TEG. achieving a higher output power of 16.61 W.

“During the optimization of advanced redox electrolytes/electrodes, the energy efficiency can reach 49.63% at 21 concentration ratios, which is 5.06% higher than that of CPV-TEG, and shows 22.65% lower total cost” , said Liu. “It can to some extent overcome the technical bottlenecks of high cost and low efficiency in current CPV-TEG hybrid systems. It can be widely applied in energy supply stations such as distributed cogeneration and concentrated photovoltaic power plants.”

The system was introduced in the newspaper “A new concentrated hybrid system with photovoltaic and ionic thermocells for the full spectrum of solar cascade use”, which was recently published in Applied energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.