Researchers from Delft University of Technology have fabricated an interdigitated back contact and heterojunction solar cell that uses a thin molybdenum oxide layer over the entire surface as a blanket layer. The device reportedly provides well-passivated gaps between electron and hole collection regions.

Scientists from Delft University of Technology in the Netherlands have designed a solar cell with an interdigitated back contact (IBC) and heterojunction (HJT) architecture that uses an electron collection contact stack based on molybdenum oxide (MoO).X).

MooingX is a transition metal oxide (TMO) nanomaterial that has both novel nano effects and excellent semiconductor properties.

“We demonstrate that using such a thin MoOx minimizes shunting losses due to its low lateral conductivity, while enabling the simplified fabrication process,” the study’s lead author Katarina Kovačević told us. pv magazine. “In the presented structure, MoOx acts as a hole transport layer, while electron collection takes place via a new layer stack.”

The research group explained that in the proposed cell design, the gaps are captured by a stack formed by a thin intrinsically hydrogenated amorphous silicon (a-Si:H) layer, the MoOXAnd transparent conductive oxides (TCO), while electrons are collected through a blanket layer made with a-Si:H, nc-Si:H, MoOXand TCO.

“MooingX was selected because it is characterized by lower lateral conductivity compared to doped hydrogenated nanocrystalline silicon (nc-Si:H),” the researchers said. “In the proposed architecture a thin MoOX layer is deposited as a blanket layer on the entire back of the device on a pre-patterned nc-Si:H layer.”

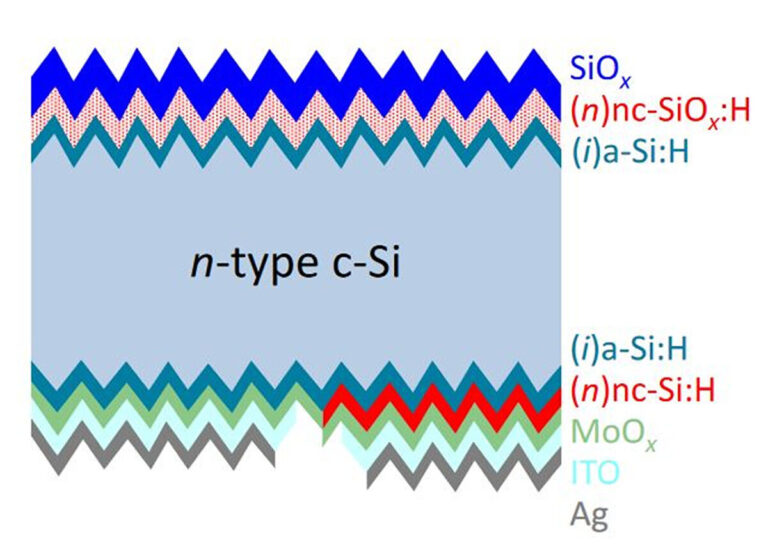

The scientists built the cell with an indium tin oxide (ITO) substrate, the blanket layer made with a-Si:H, nc-Si:H, MoOXan absorber made of n-type monocrystalline silicon, passivating contacts based on polysilicon and silicon monoxide (SiOX), and a silver (Ag) metal contact.

Image: TU Delft, Progress in Photovoltaics, Creative Commons License CC BY 4.0

“In addition to the new contact stack, our architecture is a great platform for testing industry-relevant processes,” Kovačević further explains. “First, Ag-free and ITO-free contacts can be easily implemented. Second, the industry can benefit from increased throughput because TMOs can be deposited much faster than p-type thin silicon films. Third, our highly efficient IBC solar cells could become cost-effective ingredients for future three-terminal perovskite-silicon tandem devices.”

The research team tested the performance of a 4.05 cm2 solar cell built with this configuration under standard lighting conditions and the device was found to achieve an energy conversion efficiency of 21.14%, an open-circuit voltage of 689 mV, and a short-circuit current density. of 39.02 mA/cm2 and a fill factor of 78.61%.

The academics attributed the good performance of the champion device to the optimization of the fabrication flowchart and the precise photolithographic patterning, which they said guaranteed well-defined and well-passivated gaps between electron and hole collection regions.

“Guided by optoelectric simulations, further optimization of the manufacturing process, refinement of plasma treatments, MoOX And (NThe )nc-Si:H layer and the introduction of improved ARC(s) are expected to enable efficiency improvements of well above 24% in the short term with the proposed architecture,” she added.

The new cell architecture was introduced in the article “Silicon heterojunction solar cells with interdigitation and back contact with new MoOX-based contact stacks,” published in Progress in photovoltaics.

The same research group built an HJT cell based on a MoO in 2022X hole collector. The device achieved an energy conversion efficiency of 23.83% and a fill factor of 82.18%. “The certified efficiency is – as far as we know – the highest yet on this type of device,” Isabella said at the time. “The previous record was previously certified by Ecole Polytechnique Federale de Lausanne (EPFL) at 23.5%.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.