The National Renewable Energy Laboratory developed a proof of concept for a method to remove polymers from solar panel production to enable more efficient recycling.

Solar panels are highly recyclable, but using thin plastic layers to encase solar cells can create challenges in effectively recycling valuable materials such as silicon or silver.

The U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) has developed a proof-of-concept that helps reduce the use of polymers by creating direct glass-to-glass welds in solar cells.

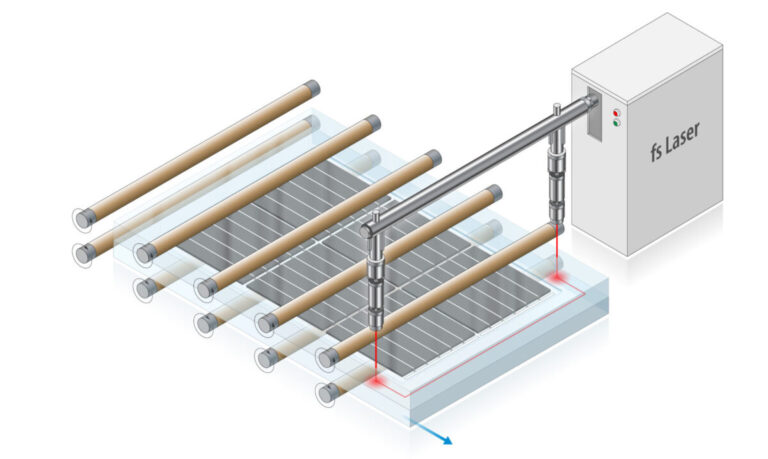

The method uses femtosecond lasers, a type of infrared laser that focuses energy on a very short time scale with a single laser pulse. The laser creates hermetically sealed glass-to-glass welds. Femtosecond lasers are currently used in medical eye procedures such as cataract surgery.

The laser welding would eliminate the need for plastic laminates, which makes recycling more difficult. At the end of their life, the modules made with laser welding can be crushed, and the glass and metal wires within them can be recycled and the silicon reused.

“Most recyclers will confirm that the polymers are the main problem when it comes to inhibiting the recycling process,” said David Young, senior scientist and group manager for the High-Efficiency Crystalline Photovoltaics group in NREL’s Chemistry and Nanoscience division.

NREL published the study in the IEEE Journal of Photovoltaics. The authors said the laser is cell material agnostic and can be used with silicon, perovskites and cadmium telluride, among others, because the heat from the highly focused laser is limited to a few millimeters. The researchers said that the welds in the glass are essentially as durable as the glass itself.

“As long as the glass doesn’t break, the weld won’t break,” Young said. “However, because there are no polymers between the glass plates, the welded modules must be much stiffer. Our paper showed that with proper assembly and adjustment of the relief characteristics of the rolled glass, a welded module can be made stiff enough to pass static load tests.”

In the past, another type of edge sealing was tried using nanosecond lasers and a glass frit filler, but the welds proved too brittle for use in outdoor module designs. The femtosecond laser welds provide superior strength with hermetic sealing at an attractive cost, according to NREL.

The research was conducted through the Sustainable Module Materials Consortium, which aims to extend the lifespan of solar panels to 50 years or longer.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.