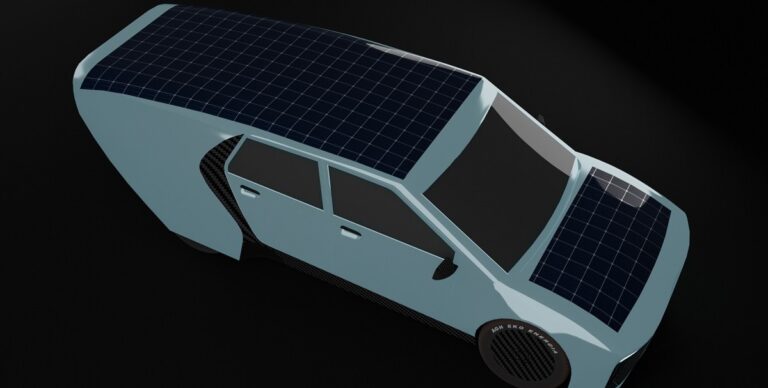

A university team in Poland has developed lightweight bifacial vehicle integrated PV (VIPV) mini modules with back contact cells and fiber optic reinforced composite plates. Manufactured in a cheap process, larger versions of the device are planned for use in a tailor -made sun streams for international competitions.

Researchers from the AGH University of Krakow in Poland and its Eko-Energia AGH Student Group have published an investigation on their approach to lightweight Bifacial vehicle integrated PV (VIPV) modules, with front and rear fiber optic-advanced composite stadium research.

“The modules that we have developed use fiber optic-reinforced plates/mats on both the front and back of the modules. This makes the modules bifacial, resulting in a slightly higher energy output for a certain area, ”said Padepep Padhamnath, university lecturer, AGH University of Krakow, and research leader, said PV Magazine.

The biggest challenge when manufacturing the modules was the design of the right material layer that offers the optimum combination of optical transparency, strength and flexibility. “Although we have shown only five piles in the newspaper, we have tested more than 20 different low combinations based on the simulation results,” said Padhamnath.

The optical characteristics of the prepared laminates were measured using a UV-fish spectrometer and simulated power voltage characteristics were tested with a light laboratory PV simulator. The team noted that it was able to calculate the final optical properties, but the mechanical properties could only be tested experimentally. “The layers that the best optically performed had insufficient mechanical properties,” Padhamnath explained.

The five proof-of-concept modules were made with interdicted back contact (IBC) solar cells and a variety of GRCF weights for the front and behind layer to find the best combination for weight, costs, solar transmissivity and mechanical strength restrictions.

The scientists swing two IBC cells between layers of GFRC sheets with the resin pulled under vacuum and cure at room temperature. The modules were prepared without using a stringer or laminator. The low GRCF mat on the front, and another layer of twill-wave fiberglass reinforced composite fabric (TW-GRCF) on the back, varied in weight from 50 g/m2 to 150 g/m2 and at the back of 150 g/m2 to 450 g/m2. A standard PV glass that was 3.2 mm thick and 7200 g/m2 was used as a reference. All prototypes had the same encapsulation film.

The stack with the 50 g/m2 GRCF on the front and 250 g/m2 TW-GRCF at the back was selected for further testing. The group noted that further development of a softer peeling process or automation of the peeling process could make the use of the lighter GRFC material of the lighter weight possible.

Another aspect of the study investigated material from the end connectors, in which the performance of aluminum (AL), copper (CU) and Nikkel (NI) connectors were compared. The electroluminescence of the team (EL) and power drainage (IV) measurements revealed that the NI alloy made the lowest relative demolition possible. Cracks were observed in AL -modules, but were not observed in modules with CU or Ni -Connectors, the group said.

Further details of the work were shared in “Development of cheap lightweight C-Si Photovoltaic modules for applications in VIPV“Published on SSRN.

“The next step is scaling up and making large modules that must be integrated into the vehicle. The EKO Energia team builds the body of the vehicle all over again on their manufacturing facility at the university. We have the design and concept of integrating modules in the body/surface of the vehicle during manufacture, “said Padhamnath.

The relegation tests module were performed at the Solar Energy Research Institute of Singapore (SERIS) at the National University of Singapore (NUS).

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.