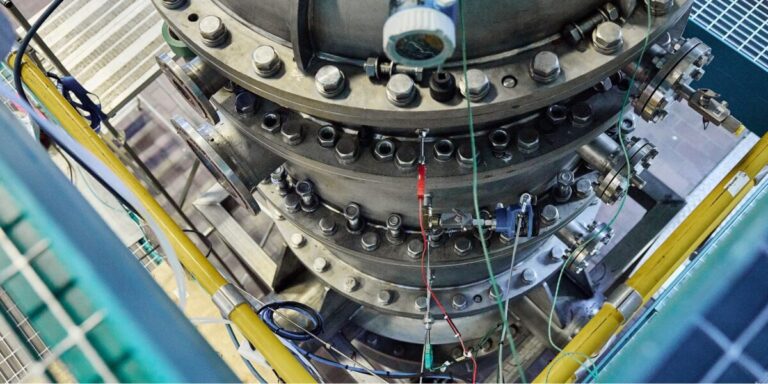

The Green14 of Sweden samples material from the pilot reactor at KTH Royal Institute of Technology. The pilot has a plasma capacity of 100 kW with 5 kg/h silicon.

Green14, a start-up company located in Sweden, has built a pilot reactor to refine Silicon and Silaan based on its new hydrogen plasma technology at the KHET-Royal Institute of Technology of Sweden.

The batch production process with 100 kW plasma capacity can produce 5 kg/h silicon with a lot of purity or the same amount of silaan.

“Our goal is to optimize the energy needed to produce silicon and Silaan to scale. By the end of this year we want to achieve a stable production of 5 kg/h, in accordance with the nominal 100 kW -current requirement of our plasma system, ”Adam Podgorski, Green14 CEO said, said PV Magazine. “What distinguishes us is our ability to produce silicon in melt shape, reconsider for purity of sun plans, but also our ability to produce Silans directly from quartz, bypass the conventional chloring route.”

The company generates samples for future customers with the “purity levels needed for commercialization,” said Podgorski, which adds that the go-to-market strategy of his company is to licensed the production technology to existing polysilicon and silaan manufacturers.

The primary output and by -products from Green14 are adjustable. “We have the flexibility to adjust the reactor to only produce monosilan for battery applications, if necessary,” said Begüm Ucun, Pilot Lead and Senior Process Engineer of Green14, PV -Magazine.

In the meantime, her team characterizes monsters and works towards configuration optimization. “Our focus is not only on material output, but also on validating our numerical models through linked thermal systems and precise measuring instruments,” said Ucun. “Data collection is the key to guarantee the efficiency and accuracy of our process.”

Based on the results of the pilot, a milestone decision will be made about a demonstration production place in Q3 2025. “For us to invest in a complete demonstration line, which was operational in 2027, we must validate the pilot’s configuration and confidence in its scalability,” said Podgorski.

Green14 strives for cost-restricting and a “CO2 footprint that is 95%” lower than today’s processes. An aspect of its sustainability is raw material flexibility. “We are dedicated to the use of lower quality silicon input to reduce the dependence on new mined agents,” said Podgorski, adding that there is also potential for the use of recycled PV panel material.

The pilot factory in KTH is expected to take approximately five years after a demonstration site has been built. It offers an R&D support to improve production processes. “Moreover, we will investigate how our technology can be applied to other critical raw materials that go beyond silicon – such as copper, aluminum, nickel and rare earth elements such as Neodymium,” said Podgorski, which indicates the first screening study of such materials to start soon.

Green14, which was founded in 2021, recently raised € 2 million ($ 2.18 million) from INGKA Investments in the Netherlands, the investment arm of INGKA Group, the largest IKEA retailer. The financing round included “a royalty -based model” with the option to buy silicon in a purchase contract.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.