Researchers at Kuwait University investigated the relationship between the molecular weight of the extinguishing gas and the morphology of perovskiet films used in solar cells, and discovered that Argon and Helium extended the lifetime of the device compared to the use of the more conventional nitrogen.

A research team of Kuwait University compared the effects on grain size, crystallinity, surfaceness, defects of the solar cell and related solar cell performance of helium and argon-extinguishing gases with nitrogen. Nitrogen, it noticed, is usually used as a low costs and a large area compatible way to create the correct crystallization of the perovskiet layer.

“I expected to see various initial asset conversion -efficiency, but I was very surprised to see that the use of inert gases with different molecular weight leads to changing the operational lifespan of the solar cell,” Afshin Hadipour said the corresponding author of the research PV Magazine.

The study did indeed show that perovskiet films extinguish with helium, because the lightest gas, and Argon, had the heaviest, larger grain sizes and were “very stable” under operational conditions compared to a device that was processed by nitrogen gas, which had a smaller grain size.

Characterization of surface effects, crystal size and grain formation was carried out via scanning electron microscopy (SEM), atomic power microscopy (AFM) and post-glowing XRD relief (XRD). Further tests include solar simulation in a nitrogen-filled glove box and opto-electronic tests that include photooluminescent (PL), external quantum efficiency (EQE) and time-losty photooluminescent (TRPP) spectroscopy measurements.

“Average lifelong weights of three perovskiet layers with three different gases were compared with the longest exciton lifetime for film extinguished with helium gas followed by nitrogen and argon bags respectively,” the scientists noted.

They also noted that the tracking results of the maximum power point (MPP) under lighting with 25c at 25c, extinguishing the device with nitrogen gas is an order of size less stable “compared to stable solar cell devices that extinguish helium and argon.

Looking at the results of the testing sequences, Hadipour explained that although the devices with all three gases started with comparable results of the power conversion (PCE) of around 20%, there was a “huge difference” in the lifetime of the solar cells under operational conditions.

The active layers of perovskite with helium and argon had almost no demolition and showed a PCE similar to the initial power conversion performance, “while the device was extinguished with nitrogen, was left with only about 50% of the initial efficiency.”

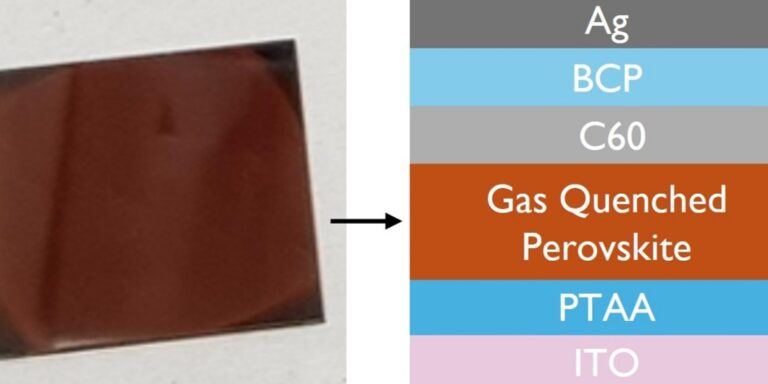

The devices used in the experiment were reverse pin-type devices with glass substrates of 9 cm2 and based on a Formamidinium -sium (FA-CS) Dual Kation Perovskiet recipe with a 1.6 EV band gap. In a NIP sunscreen, the device is relieved by the side (ETL) side of the electron transport layer (while a pin -structure is relieved by the surface of the hole transport (HTL).

The stack was as follows: Indium tinoxide (ITO), polymer transport layer made of poly (triarlamine) (ptaa), gas extinguished perovskiet, buckminsterfullereen (c60) electron transport layer (ETL), a Bathocuprine (BCP) buffer and silver.

The team claimed that the alternative extinguishing method is compatible with a variety of coating tools and has potential for production purposes on a large scale.

“Of course, different inert gasses must be tested and compared to each other for each type of perovskiets composition and forerunner’s solution to find the optimum extinguishing condition for each individual case,” it added.

The research cooperation with the researchers from the Belgian research institute Imec, according to Hadipour. It is described in “Improving the method for gas association for the manufacture of photovoltaic photo on Perovskiet‘In the Kuwait Journal of Science.

In the future, the group will concentrate on challenging the gas of different perovskiet compositions and with different solvents systems.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.