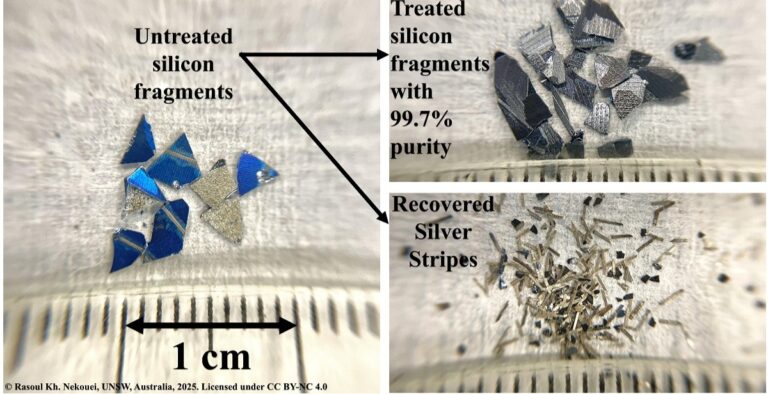

UNSW researchers could recover silicon from PV panels from the end of life purely enough for reuse in devices based on silicon carbide. Their new multi -step method that includes thermal and chemical processes also recovers silver.

A team from the Australian University of New South Wales (UNSW) in Sydney reported that the silicon, silver and tin could recover from PV cell layers. The method recovered most of the silver (AG) (70 gestation) and the processed silicon (SI) exceeded 99.7 gain% purity.

The method is described in “Microrecycling of waste solar cells via an in-situ Fluor-generating thermal treatment for silicon recovery with high purity recovery‘Published by Sources, preservation and recycling.

The micro-recycling approach makes the selective recovery and transformation of valuable materials on micro-scale possible, according to Rasoul Khayam Nekouei, corresponding author of the research, rather than trusting traditional Bulkrecycling methods.

“It also refers to the characterization techniques of the micro -scale that are used to investigate the recovery mechanisms of valuable metals,” he explained.

In the study, the manual separation of the connection box, cables and aluminum alloy frame is followed by the Module Glass Delamination via a hydrothermic offense method, which was developed by the study authors in earlier research.

Subsequently, the waste cell material was subject to a heat treatment of average temperature at 550 ° C, so that the ethylene vinylacetate (EVA) encapsulantia and polyvinyl fluoride (PVF) were effectively removed. The “in-situ F-producing thermal treatment” medium temperature “was able to eliminate the corrosion resistance that was administered by the upper layer of the silicon (SI) cell, according to the team.

“The biggest surprise was to discover that Fluor, who breaks this corrosion -resistant layer, was already present in the rear scale of the solar panel. This meant that the problem and the solution were the solution side by side, “Nekouei said PV Magazine.

In the second step, both the heat-treated silicon (HT-Si) and untreated (UT-Si) fragments underwent chemical etching using basic 30 wt% potassium hydroxide (KOH) and nitric acidic (20 v% HNO3) media at 80 C. Surface roughness and elemental analyses supported decisions about how long to perform etching to remove aluminum (al) from the ht-si and ut-si fragments.

The two-step sets removed Alon’s Cleans within 3 minutes and ‘facilitated the liberation of 70 getting. The remaining AG and SN were extracted with the help of the second etching stage via an acid media, “said the researchers.

The team said it was worth noting that the SI purity of the back of UT-SI fragments remained about 77%, while those of HT-Si fragments were the 99 wage.

The et process not only prevented SI loss, but also facilitated the mechanical withdrawal of more than 70 gestation% of the AG strips.

It was noted that the heat treatment of the medium temperature “can significantly reduce the duration of both etching steps, making it easier to restore si fragments with high purity (≥99.7%).” Moreover, for the removal of lead (PB), 10 minutes of sour etchings proved sufficient, although longer duration did not show any adverse effects on its recovery, according to the team.

As a demonstration of upcycling in high-quality products, the team processed purified HT-SI fragments (P-HT-SI fragments) with 99.7 Gew.% Purity to produce beta-silicon carbide (β-sic) waffles. Analysis revealed that the SIC had a mix of sub-micron particles, “nanoparticles and nano-whisquers coated with a SIO2 scale of thickness 2-3 Nm.” The resulting material was considered suitable for microgolf absorption applications, such as gas sensors.

The team concluded that the “micro-recycling method” offers a “sustainable path in the direction of minimizing waste when recycling best photovoltaic solar cells.”

Looking ahead, the research team will explore a wider range of waste solar panels, optimize the process to improve repair efficiency and material purity and to investigate possible commercialization possibilities, according to Nekouei. “Moreover, we are planning to use the purified silicon in advanced applications, such as detection and energy storage.”

Nekouei added that commercialization would do further research, to assess feasibility, the viability of the market, to evaluate the competitiveness and evaluate potential business models.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.